Understanding Prototype Services in Medical Device Development

Discover the essential role of prototype services in medical device development and...

Product development technologies are transforming the medical device industry by bridging innovative design with patient care. These advancements not only improve the efficiency of product development but also ensure compliance with stringent safety and regulatory standards. As the healthcare landscape continues to evolve, companies face a critical question: how can they harness these technologies to enhance patient outcomes while maintaining a competitive edge? A closer examination of these technologies uncovers a landscape rich with opportunities and potential challenges that could significantly influence the future of medical innovation.

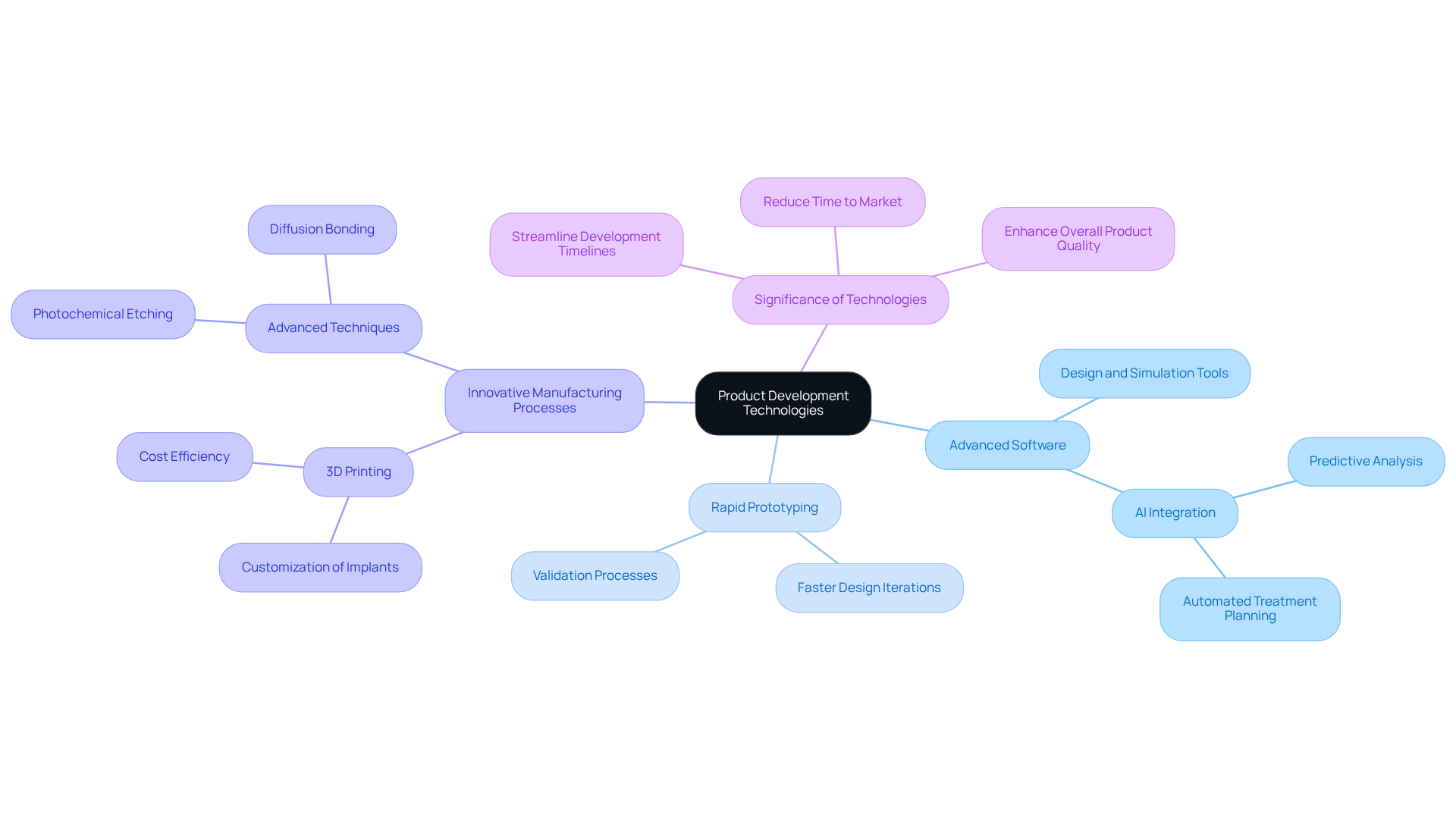

Product creation methods encompass the essential instruments, approaches, and procedures involved in the design, development, and production of healthcare instruments, particularly focusing on product development technologies. These innovations are critical for ensuring that products meet safety, efficacy, and regulatory compliance standards. Key components include:

The importance of product development technologies is highlighted by their capacity to:

This progression leads to improved outcomes for patients and greater efficiency within the healthcare system. For instance, the integration of AI and robotics in healthcare tools is transforming care by enabling predictive analysis and increasing surgical precision, ultimately shortening recovery times and improving treatment for chronic conditions.

As the healthcare technology sector evolves, a focus on human-centered design and adherence to regulatory frameworks will be essential for fostering innovation and ensuring that products effectively address patient needs. With the global healthcare equipment market projected to grow significantly, Voler Systems' expertise in developing groundbreaking health solutions positions them as a leader in this dynamic landscape.

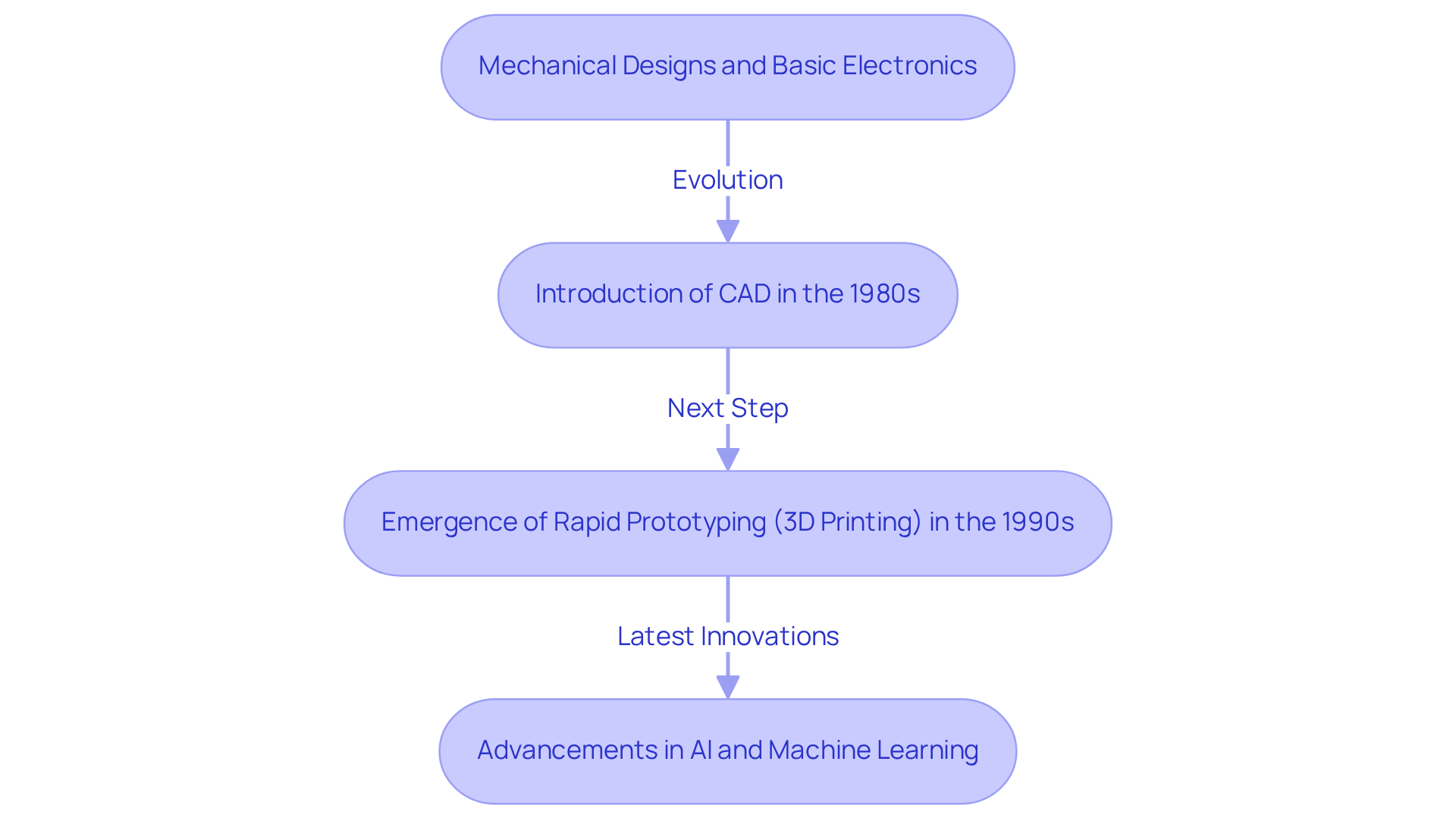

The advancement of product development technologies in the medical device sector has been characterized by significant milestones that have shaped its landscape. Initially, the focus was on mechanical designs and basic electronic components. The introduction of computer-aided design (CAD) in the 1980s represented a transformative shift, facilitating the creation of more precise and complex designs. By the 1990s, the emergence of rapid prototyping techniques, particularly 3D printing, allowed for quicker iterations and testing of prototypes, thereby enhancing the development process.

Recent advancements in artificial intelligence (AI) and machine learning are further revolutionizing product development technologies, enabling improved predictive analytics and the automation of various design tasks. For instance, custom implants developed using 3D CAD have demonstrated higher success rates and reduced surgical risks, underscoring the tangible benefits of these innovations. This historical context highlights the ongoing pursuit of innovation within healthcare equipment development, driven by the imperative for enhanced patient outcomes and streamlined processes.

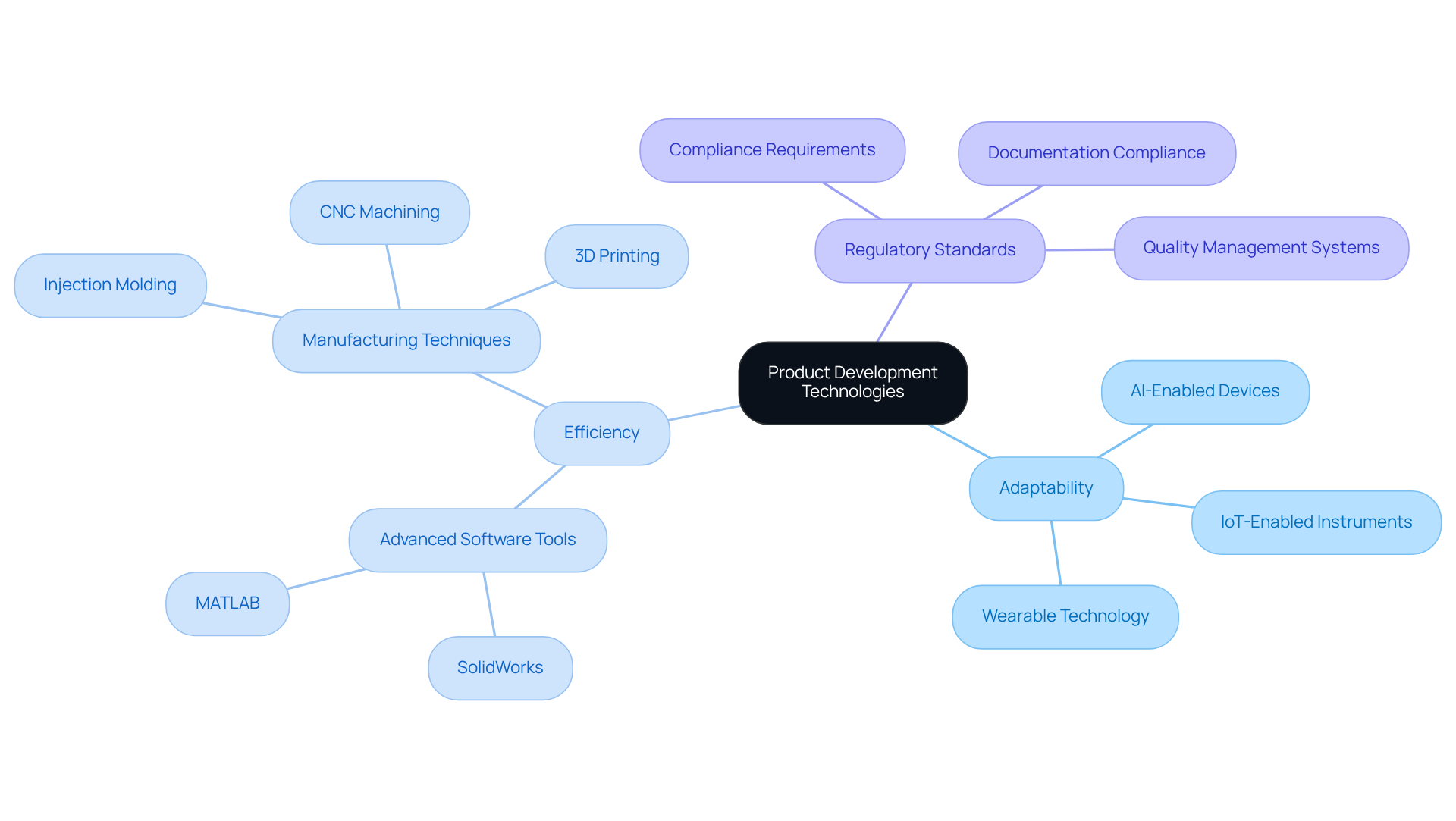

Key features of product development technologies encompass adaptability, efficiency, and strict adherence to regulatory standards, particularly within the medical equipment sector. Essential components include:

Notably, software platforms such as SolidWorks and MATLAB are extensively employed for design and analysis, allowing engineers to develop precise models and simulations that inform decision-making. Manufacturing technologies like injection molding and CNC machining are crucial in producing high-quality components that satisfy industry demands.

Moreover, the integration of artificial intelligence into design processes significantly enhances data analysis capabilities, facilitating more informed decisions and streamlining development workflows. IoT-enabled instruments exemplify the importance of adaptability and efficiency, as they gather real-time patient data, thereby transforming patient care and functionality. However, the creation of new hardware from scratch is a complex process that requires continuous attention to documentation compliance, especially for startups in the medical equipment sector. Recognizing common errors in manufacturing tests is essential for ensuring quality and efficiency in electronic product design.

The healthcare sector is undergoing a transformative shift driven by innovation, patient expectations, and regulatory changes, underscoring the necessity for compliance in product development technologies. Collectively, these characteristics and elements are vital for the successful development of innovative healthcare products through product development technologies, ensuring they are not only effective but also compliant with evolving industry standards.

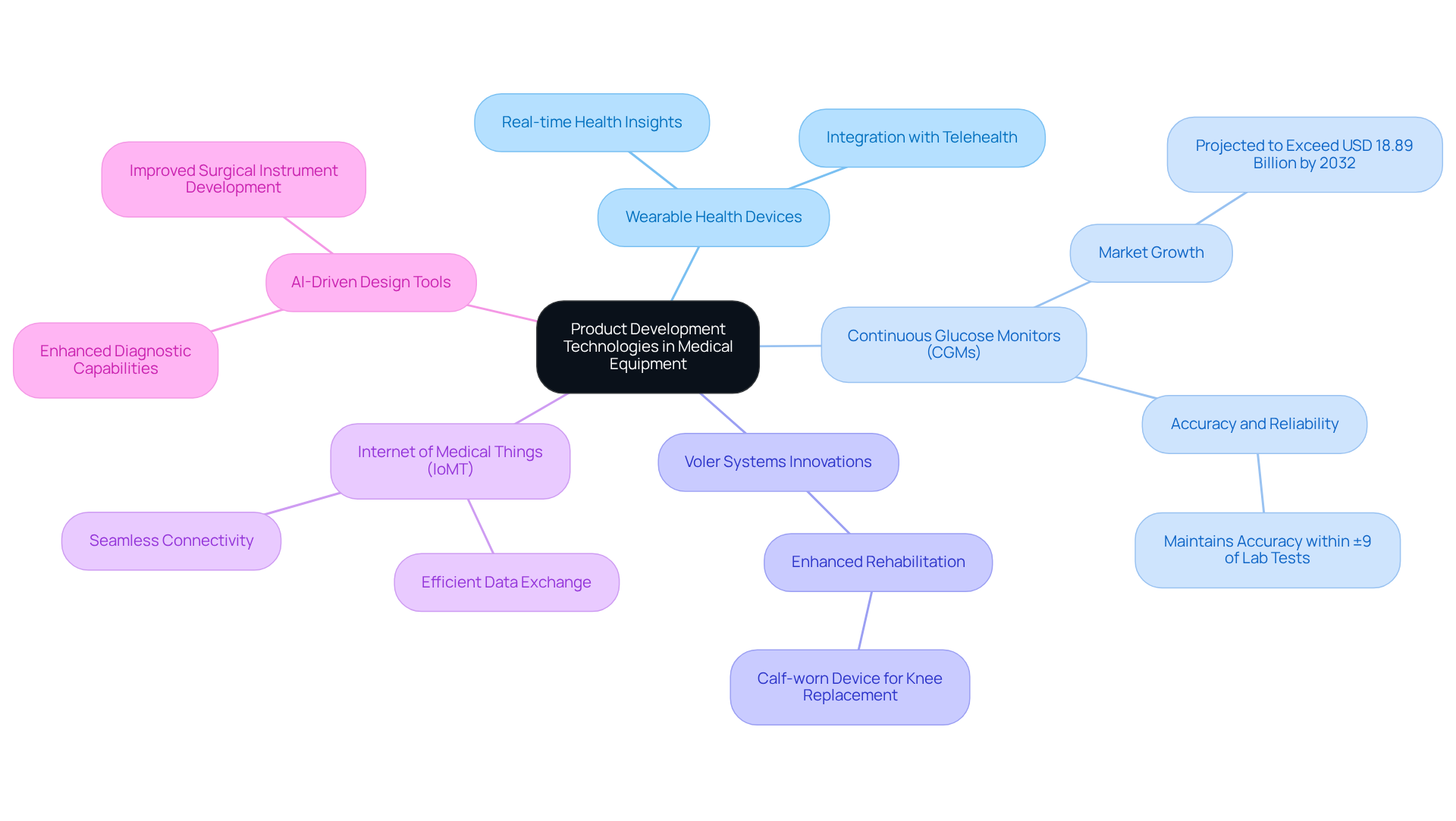

The medical equipment industry is witnessing significant advancements, especially in product development technologies related to wearable health devices. Continuous glucose monitors (CGMs) serve as a prime example of this integration, utilizing advanced sensors and data analytics to provide real-time health insights that empower individuals to effectively manage their conditions. The global CGM market is anticipated to surpass USD 18.89 billion by 2032, indicating a growing demand for such innovative solutions.

Voler Systems is at the forefront of this innovation, having developed a calf-worn device that detects motion and measures circumference, specifically designed to enhance rehabilitation adherence for individuals undergoing knee replacement. This device not only showcases Voler Systems' expertise in electronic motion detection but also adheres to stringent medical equipment standards, ensuring safety and efficacy in healthcare applications.

The Internet of Medical Things (IoMT) plays a crucial role in this landscape, enabling seamless connectivity between devices and facilitating efficient data exchange for improved healthcare management. For example, the FDA-approved Current Health AI wearable device allows individuals to monitor multiple vital signs at home, bridging the gap between hospital care and daily health management.

Furthermore, AI-driven design tools are transforming the development of surgical instruments, enhancing precision and reducing errors. A notable instance is the implementation of AI systems at Northwell Health, which aims to streamline clinical note-taking and bolster diagnostic capabilities, ultimately leading to improved outcomes for patients receiving care.

These advancements highlight the essential role of product development technologies in enhancing medical device capabilities while also promoting a culture of proactive patient engagement and improved healthcare delivery.

The exploration of product development technologies in the medical device sector highlights their crucial role in shaping innovative healthcare solutions. These technologies enhance design and manufacturing processes while ensuring compliance with safety and efficacy standards, ultimately leading to improved patient outcomes. As the healthcare landscape evolves, integrating advanced tools and methodologies becomes essential to meet the industry's growing demands.

Key insights from this discussion emphasize the importance of:

Historical milestones, such as the introduction of CAD and the emergence of AI, have revolutionized product development, facilitating quicker iterations and more precise designs. Real-world applications, including wearable health devices and the Internet of Medical Things (IoMT), exemplify how these technologies actively enhance patient care and engagement.

As the healthcare technology sector continues to expand, embracing these advancements is crucial for stakeholders aiming to innovate and improve healthcare delivery. The imperative is clear: stakeholders must prioritize the adoption of cutting-edge product development technologies to not only keep pace with industry changes but also to lead in delivering effective and compliant medical solutions that genuinely address patient needs.

What are product development technologies?

Product development technologies encompass the essential instruments, approaches, and procedures involved in the design, development, and production of healthcare instruments.

Why are product development technologies significant?

They are critical for ensuring that products meet safety, efficacy, and regulatory compliance standards, leading to improved outcomes for patients and greater efficiency within the healthcare system.

What are some key components of product development technologies?

Key components include advanced software for design and simulation, rapid prototyping techniques, and innovative manufacturing processes.

How do product development technologies impact the development timelines?

They streamline development timelines, reduce time to market, and enhance overall product quality.

Can you provide examples of products developed using these technologies?

Examples include wearable devices, heart pumps, and liquid biopsy platforms.

How is AI and robotics influencing healthcare tools?

The integration of AI and robotics enables predictive analysis and increases surgical precision, ultimately shortening recovery times and improving treatment for chronic conditions.

What is the importance of human-centered design in healthcare technology?

A focus on human-centered design is essential for fostering innovation and ensuring that products effectively address patient needs.

What is the projected growth of the global healthcare equipment market?

The global healthcare equipment market is projected to grow significantly.

How does Voler Systems fit into the healthcare technology landscape?

Voler Systems is positioned as a leader in developing groundbreaking health solutions within the dynamic healthcare technology sector.