Best Practices in Electronic Product Design and Development for Medical Devices

Explore best practices for electronic product design and development in medical devices.

The medical device industry is at the forefront of innovation, propelled by rapid technological advancements and a growing demand for enhanced patient care. To navigate this dynamic landscape, organizations must master a series of best practices in product development and engineering. This mastery enables them to identify viable ideas, validate designs, and successfully bring products to market. However, the complexities of regulatory compliance and the necessity for effective commercialization strategies pose significant challenges. Thus, how can companies ensure they not only keep pace with industry trends but also lead the charge in creating groundbreaking medical solutions?

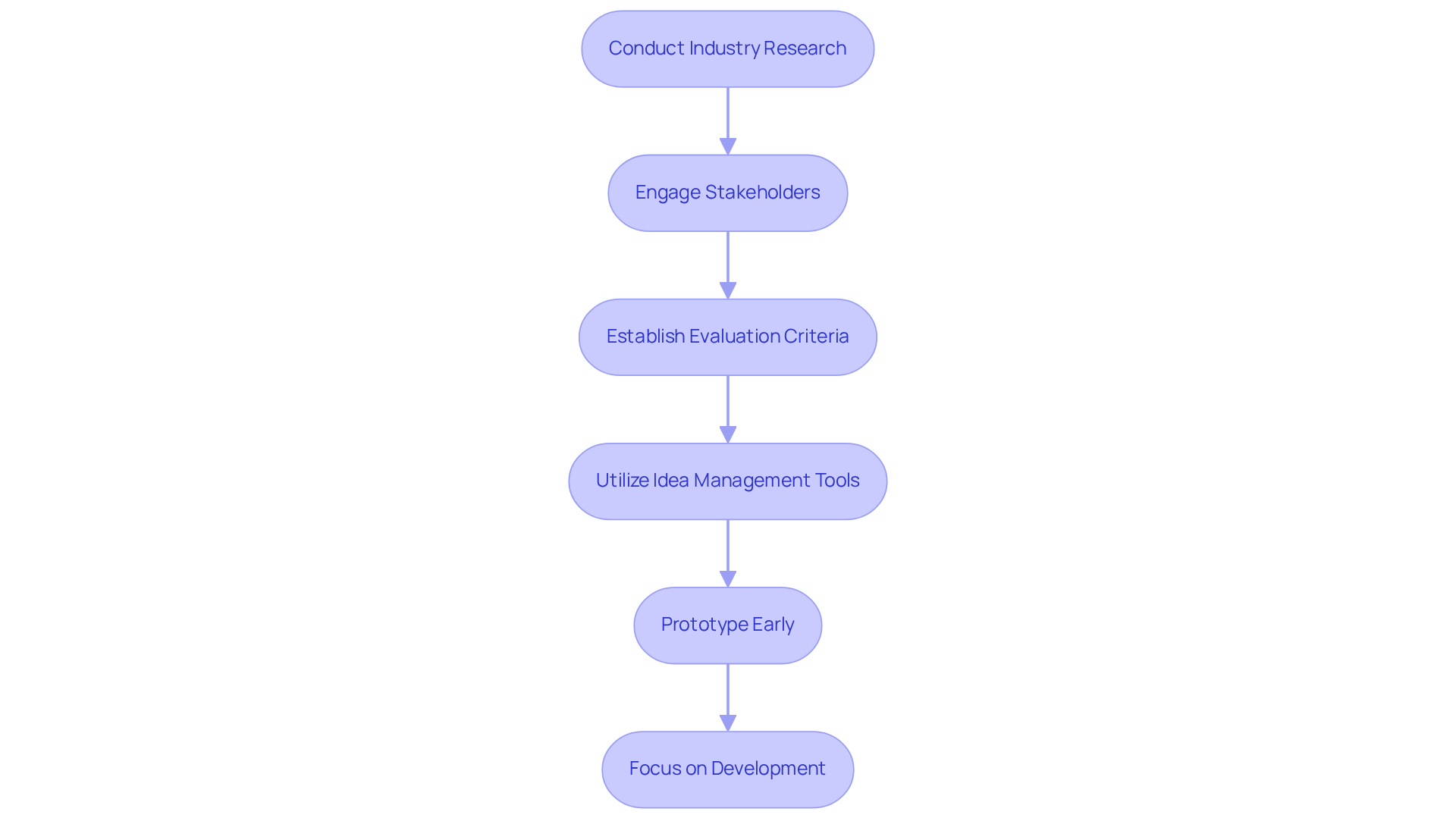

To effectively identify and screen viable ideas for medical devices, organizations should adhere to the following best practices:

Conduct Industry Research: Organizations should utilize surveys, focus groups, and sector reports to gain insights into current industry needs and gaps. This method is crucial for identifying opportunities for innovation, particularly as the healthcare equipment sector is projected to achieve substantial growth by 2026, driven by advancements in technology and patient care.

Engage Stakeholders: It is essential to involve healthcare professionals, patients, and regulatory experts early in the ideation process. Gathering diverse perspectives ensures that ideas align with real-world needs and enhances the likelihood of successful adoption. Engaging stakeholders can lead to creative solutions that address unmet needs, as emphasized by industry specialists who highlight the importance of collaboration in product development and engineering.

Establish Evaluation Criteria: Organizations should create a comprehensive set of criteria based on feasibility, commercial potential, regulatory requirements, and alignment with company capabilities. This systematic approach aids in effectively evaluating each idea, ensuring that only the most promising concepts advance in the development pipeline.

Utilize Idea Management Tools: Implementing software solutions designed to facilitate idea collection, collaboration, and evaluation is vital. These tools streamline the process, ensuring that valuable ideas are not overlooked and that the organization can respond swiftly to emerging opportunities.

Prototype Early: Developing low-fidelity prototypes allows for the visualization of concepts and the gathering of feedback quickly. This iterative method enables the refinement of concepts prior to the allocation of substantial resources, ultimately resulting in more user-focused and efficient health products.

By adhering to these steps, organizations can concentrate on the most promising healthcare technology concepts, preparing for successful development and commercialization in a rapidly evolving market.

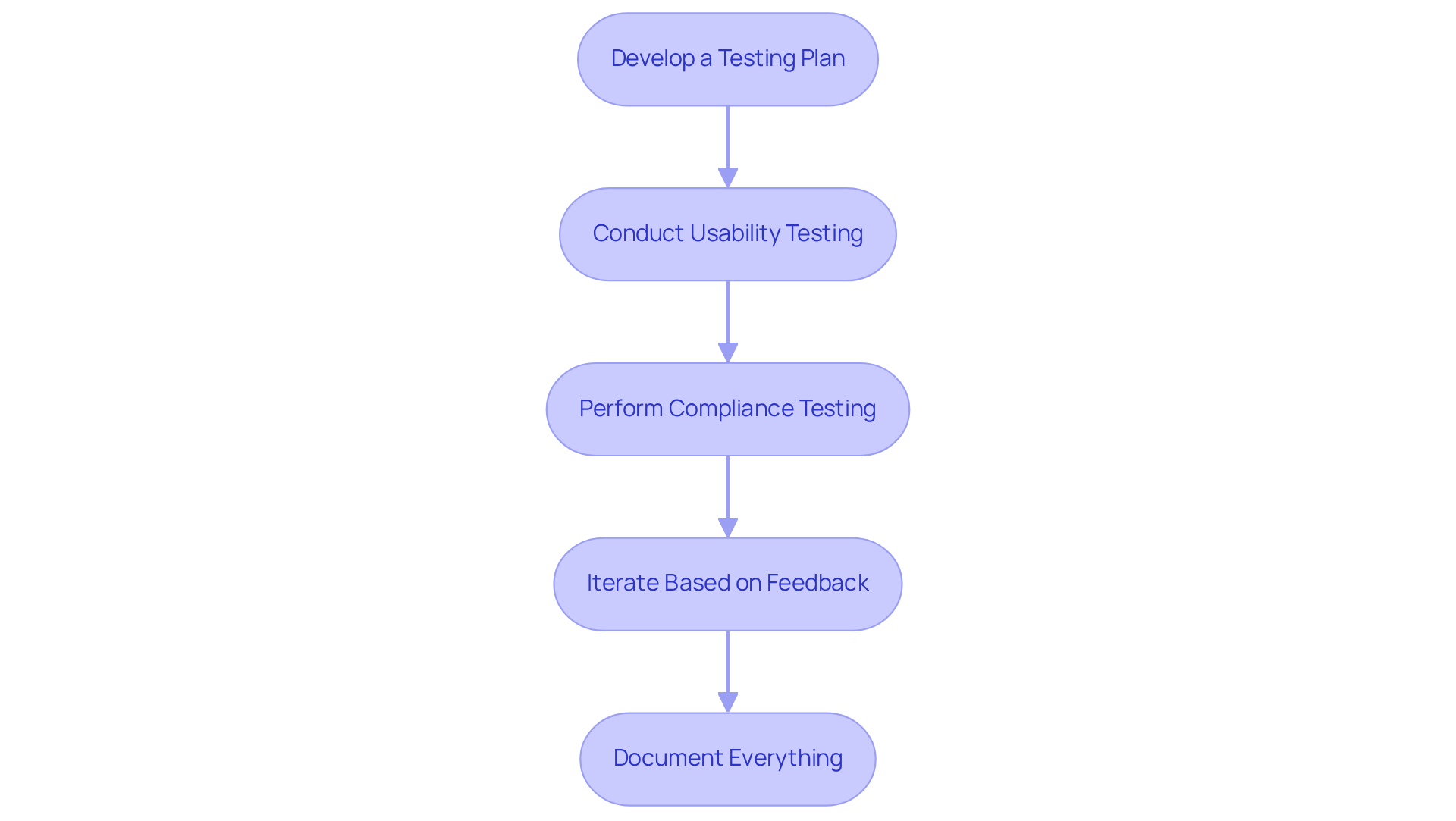

To ensure effective and compliant medical device designs, implementing best practices for prototyping and validation is essential:

Develop a Testing Plan: Clearly outline objectives, methodologies, and metrics for testing prototypes. This plan should align with regulatory requirements and user needs, ensuring comprehensive coverage of all aspects, including common errors that may arise during manufacturing tests.

Conduct Usability Testing: Engage end-users actively in testing prototypes to gather valuable feedback on functionality, ergonomics, and overall user experience. This early involvement assists in recognizing potential issues and enhances effectiveness, addressing common pitfalls in the manufacturing process.

Perform Compliance Testing: Verify that prototypes meet relevant regulatory standards, such as ISO 13485 and FDA guidelines. This includes conducting electrical safety tests, biocompatibility assessments, and performance evaluations to ensure safety and efficacy, which are crucial for documentation compliance.

Iterate Based on Feedback: Utilize insights gained from testing to continuously refine creations. Iterative prototyping fosters ongoing improvement and adaptation to user feedback, which is vital for successful product development and engineering, and helps mitigate common errors.

Document Everything: Maintain thorough records of testing procedures, outcomes, and modifications. This is vital for regulatory submissions and quality assurance, ensuring that all aspects of the development process are transparent and traceable. Additionally, referencing user manuals can enhance understanding and compliance.

By rigorously testing prototypes and adhering to best practices, organizations can confirm their designs, ensuring they are safe, effective, and prepared for launch.

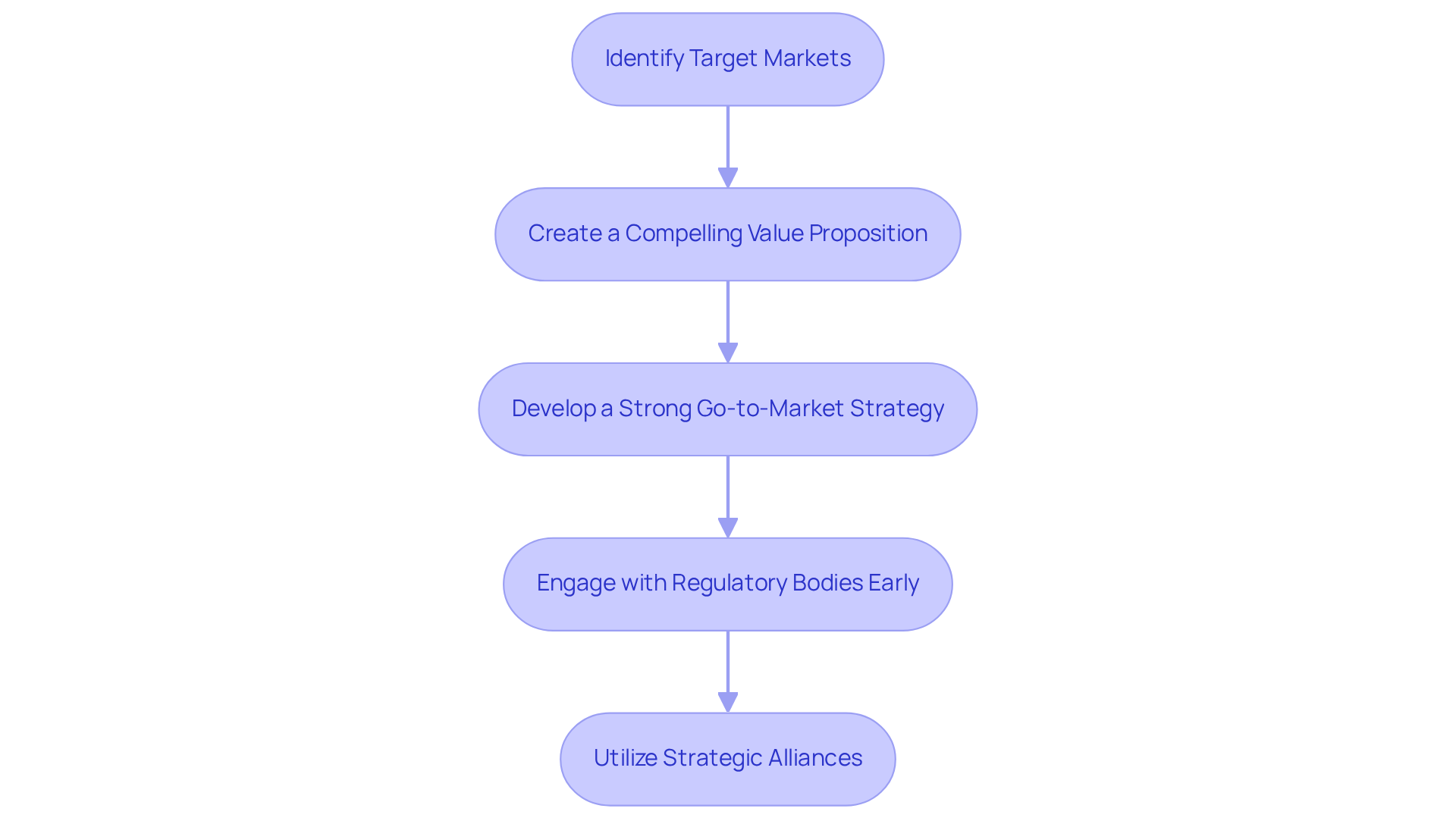

To successfully commercialize medical devices, organizations should adopt the following best practices:

Identify Target Markets: Conduct a comprehensive market analysis to pinpoint potential customer segments, focusing on their specific needs and preferences. Understanding the demographics and purchasing behaviors of stakeholders is crucial for tailoring marketing efforts effectively.

Create a Compelling Value Proposition: Clearly articulate the unique benefits of your medical product in comparison to competitors. This proposition should outline how the product resolves specific issues or improves patient outcomes, thereby resonating with over 70% of consumers who support brands aligned with their values and purpose.

Develop a Strong Go-to-Market Strategy: Outline the sales channels for the product, such as direct sales, distributors, or online platforms, and craft marketing strategies tailored to each channel. This approach ensures that the product reaches the right audience effectively.

Engage with Regulatory Bodies Early: Establish proactive communication with regulatory agencies to grasp the approval process and ensure compliance from the beginning. This strategy can reduce possible delays in industry entry, which is especially crucial considering the growing regulatory oversight in the medical equipment sector.

Utilize Strategic Alliances: Collaborate with healthcare providers, industry leaders, and other stakeholders to enhance credibility and expand outreach. Such partnerships can increase the perceived value of the product and facilitate access to competitive industries.

By applying these strategies, organizations can effectively manage the complexities of introducing healthcare products to market, significantly enhancing their likelihood of success.

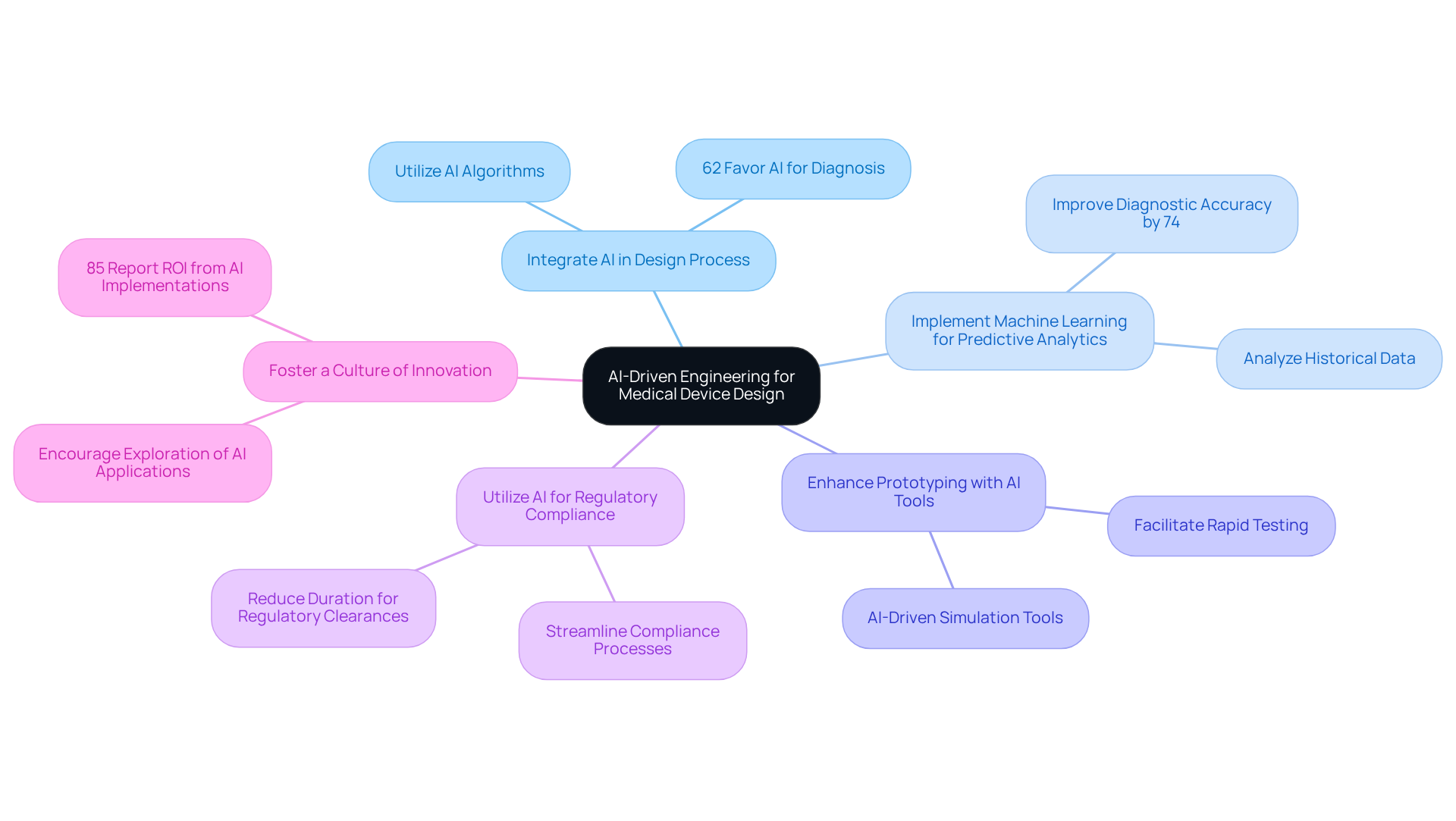

To harness the power of AI in medical device design, consider the following best practices:

Integrate AI in the Design Process: Utilize AI algorithms to analyze design data, predict performance outcomes, and optimize designs for manufacturability and user experience. This approach enhances efficiency and aligns with the growing trend of AI adoption in healthcare, where 62% of professionals favor its use for diagnosis.

Implement Machine Learning for Predictive Analytics: Employ machine learning models to analyze historical data and forecast future trends in equipment performance. For instance, predictive analytics can improve diagnostic accuracy by over 74%, significantly impacting patient outcomes and device reliability.

Enhance Prototyping with AI Tools: Use AI-driven simulation tools to create virtual prototypes, facilitating rapid testing and iteration without the need for physical models. This method accelerates the validation process, enabling quicker modifications based on user feedback and performance metrics.

Utilize AI for Regulatory Compliance: Leverage AI technologies to streamline compliance processes, ensuring that products meet regulatory standards efficiently. Timely incorporation of AI can reduce the duration needed for regulatory clearances, which is essential for compliance in healthcare product development and engineering.

Foster a Culture of Innovation: Encourage teams to explore AI applications in their workflows, promoting continuous learning and adaptation to new technologies. This cultural shift is crucial, as 85% of organizations report significant returns on investment from AI implementations within the first year.

By integrating AI-driven engineering into the design process, organizations like Voler Systems can enhance innovation, reduce time to market, and improve the overall quality of medical devices, ultimately leading to better patient care and satisfaction.

Mastering product development and engineering for medical devices necessitates a comprehensive approach that integrates research, stakeholder engagement, rigorous testing, effective commercialization strategies, and innovative technologies. Organizations must diligently identify viable ideas, develop prototypes, and validate designs to ensure compliance and effectiveness in a competitive market.

Key practices involve:

In conclusion, organizations in the medical device sector must adopt these best practices to successfully navigate the complexities of product development and commercialization. By focusing on innovation, collaboration, and adherence to regulatory requirements, companies can enhance their market position and contribute to improved patient care. As the healthcare landscape continues to evolve, staying ahead of trends and embracing new technologies will be crucial for sustaining success in the medical device industry.

What are the best practices for identifying and screening viable ideas for medical devices?

Best practices include conducting industry research, engaging stakeholders, establishing evaluation criteria, utilizing idea management tools, and prototyping early.

How can organizations conduct industry research effectively?

Organizations should utilize surveys, focus groups, and sector reports to gain insights into current industry needs and gaps, which helps identify opportunities for innovation.

Why is it important to engage stakeholders during the ideation process?

Engaging healthcare professionals, patients, and regulatory experts early ensures that ideas align with real-world needs and enhances the likelihood of successful adoption, leading to creative solutions that address unmet needs.

What should organizations include in their evaluation criteria for medical device ideas?

Evaluation criteria should be based on feasibility, commercial potential, regulatory requirements, and alignment with company capabilities to ensure only the most promising concepts advance.

What role do idea management tools play in the development of medical devices?

Idea management tools facilitate idea collection, collaboration, and evaluation, streamlining the process and ensuring that valuable ideas are not overlooked.

Why is prototyping early considered beneficial in the development of medical devices?

Developing low-fidelity prototypes allows organizations to visualize concepts and gather feedback quickly, enabling refinement before significant resources are allocated, resulting in more user-focused products.