Best Practices for AI FPGA Integration in Medical Devices

Explore best practices for integrating AI FPGA in medical devices for enhanced efficiency...

The landscape of medical device development is rapidly evolving, propelled by technological advancements and increasing regulatory scrutiny. With the Indian medical technology market projected to reach an impressive Rs. 2,177.9 billion by 2026, understanding best practices in electronic product design and development is crucial for success. This article explores the intricacies of the design process, highlighting the significance of regulatory compliance, quality control, and innovative technologies. Given the high stakes involved, how can manufacturers ensure their products not only meet market demands but also effectively navigate the complex regulatory environment?

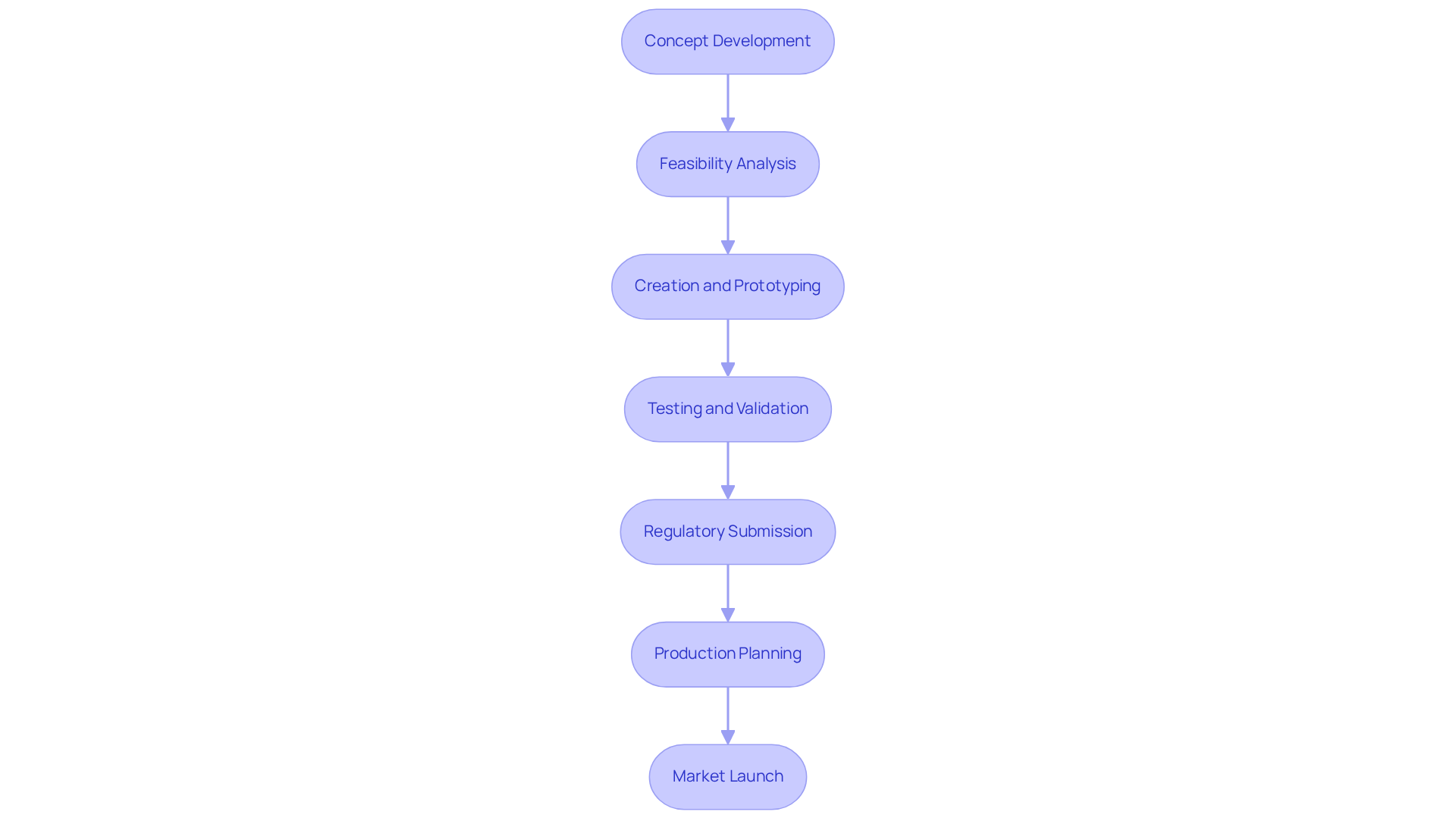

The electronic product design and development process for medical devices encompasses several critical stages that ensure successful outcomes:

Concept Development: This initial phase involves identifying the need for a new product, conducting thorough market research, and defining user requirements. Understanding market dynamics is essential, especially as the medical technology sector in India is projected to surge to Rs. 2,177.9 billion by 2026. Best practices in this stage include leveraging insights from successful case studies, such as Dexcom's Stelo Continuous Glucose Monitor, which illustrates the importance of effectively addressing user needs.

Feasibility Analysis: In this stage, technical feasibility, regulatory requirements, and potential market barriers are assessed. With the Indian government inviting proposals to reduce import dependence, manufacturers must navigate these evolving landscapes effectively. This phase should also consider the FDA's evolving evaluation processes for software-driven and AI-enabled devices, which are critical for compliance.

Creation and Prototyping: Initial concepts and prototypes are developed, emphasizing functionality and user experience. Utilizing advanced tools like CAD software ensures precision in creation, which is crucial for compliance with standards such as ISO 13485. Integrating AI technologies, backed by Voler Systems' proficiency in creating tools such as heart pumps and liquid biopsy platforms, can enhance efficiency and flexibility, particularly for wearable and IoT solutions.

Testing and Validation: Rigorous testing is conducted to validate designs against user requirements and regulatory standards. This includes usability testing and performance evaluations, which are vital for meeting the stringent demands of the FDA and other regulatory bodies. Ongoing surveillance of cybersecurity strategies is also crucial, as the significance of healthcare equipment cybersecurity continues to grow in 2026.

Regulatory Submission: Preparing and submitting documentation for regulatory approval is a pivotal step. Compliance with standards such as ISO 13485 and FDA regulations is essential to avoid common pitfalls that can delay approval. Grasping the nuances of regulatory submissions, particularly for AI-enabled products, is essential for successful market entry, a domain where Voler Systems excels.

Production Planning: Developing a comprehensive manufacturing plan involves sourcing materials, selecting suppliers, and establishing efficient production workflows. As manufacturers reassess their supply chains, strategies like reshoring are gaining traction to enhance resilience.

Market Launch: The final stage involves executing the launch strategy, which includes marketing and distribution plans. Constant oversight of post-market performance is essential for continual enhancement and adherence, particularly as the significance of healthcare technology cybersecurity continues to grow in 2026.

By following this organized method and incorporating insights from case studies and regulatory trends, engineers in the healthcare sector can significantly improve their electronic product design and development, enhancing the chances of successful product creation and market entry while ensuring that innovations satisfy both user requirements and regulatory standards.

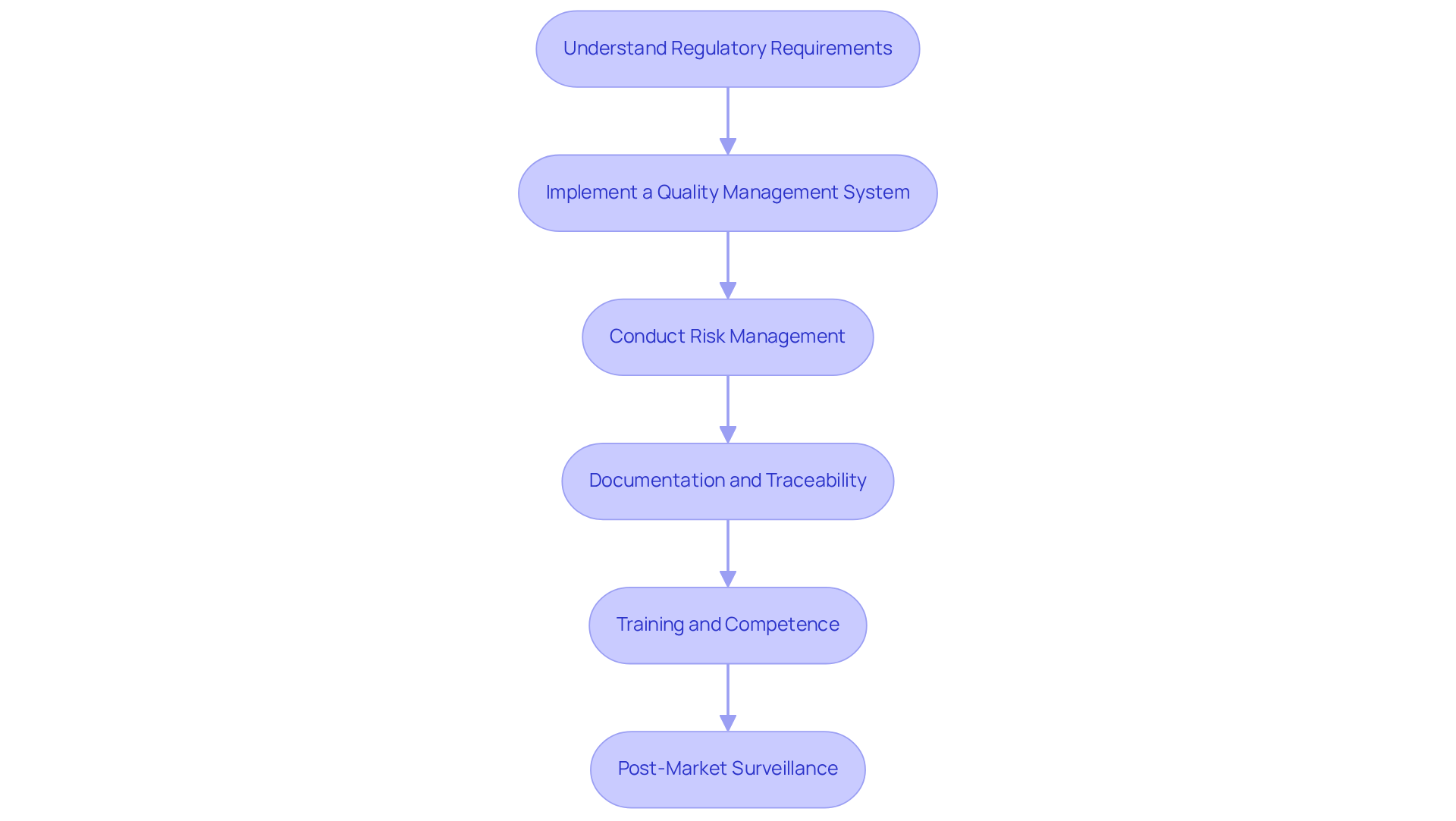

To ensure regulatory compliance and quality control in medical device development, consider the following practices:

Understand Regulatory Requirements: Familiarize yourself with essential regulations, including FDA guidelines and ISO 13485:2016. Staying informed about these standards is crucial for maintaining compliance and meeting industry expectations.

Implement a Quality Management System (QMS): Establish a comprehensive QMS that encompasses all aspects of product creation, from conception to manufacturing. Regular audits and management reviews should be integral to this system, ensuring alignment with the latest Quality Management System Regulation (QMSR) updates.

Conduct Risk Management: Perform thorough risk evaluations at each project phase to identify potential hazards and implement effective mitigation strategies. Tools such as Failure Mode and Effects Analysis (FMEA) can systematically evaluate risks, enhancing product safety.

Documentation and Traceability: Maintain meticulous records of all design and production activities, ensuring traceability of decisions and changes. This practice is vital for regulatory submissions and audits, particularly under the scrutiny of the updated compliance programs.

Training and Competence: Ensure that all team members receive adequate training in regulatory requirements and quality control processes. Continuous education is essential for maintaining compliance and improving product quality, especially as regulations evolve.

Post-Market Surveillance: Following product launch, actively observe performance and collect user feedback to identify any issues. This information is crucial for ongoing compliance and product enhancement, supporting long-term safety and efficacy.

By incorporating these practices into electronic product design and development, companies can significantly enhance product safety and efficacy while minimizing regulatory risks.

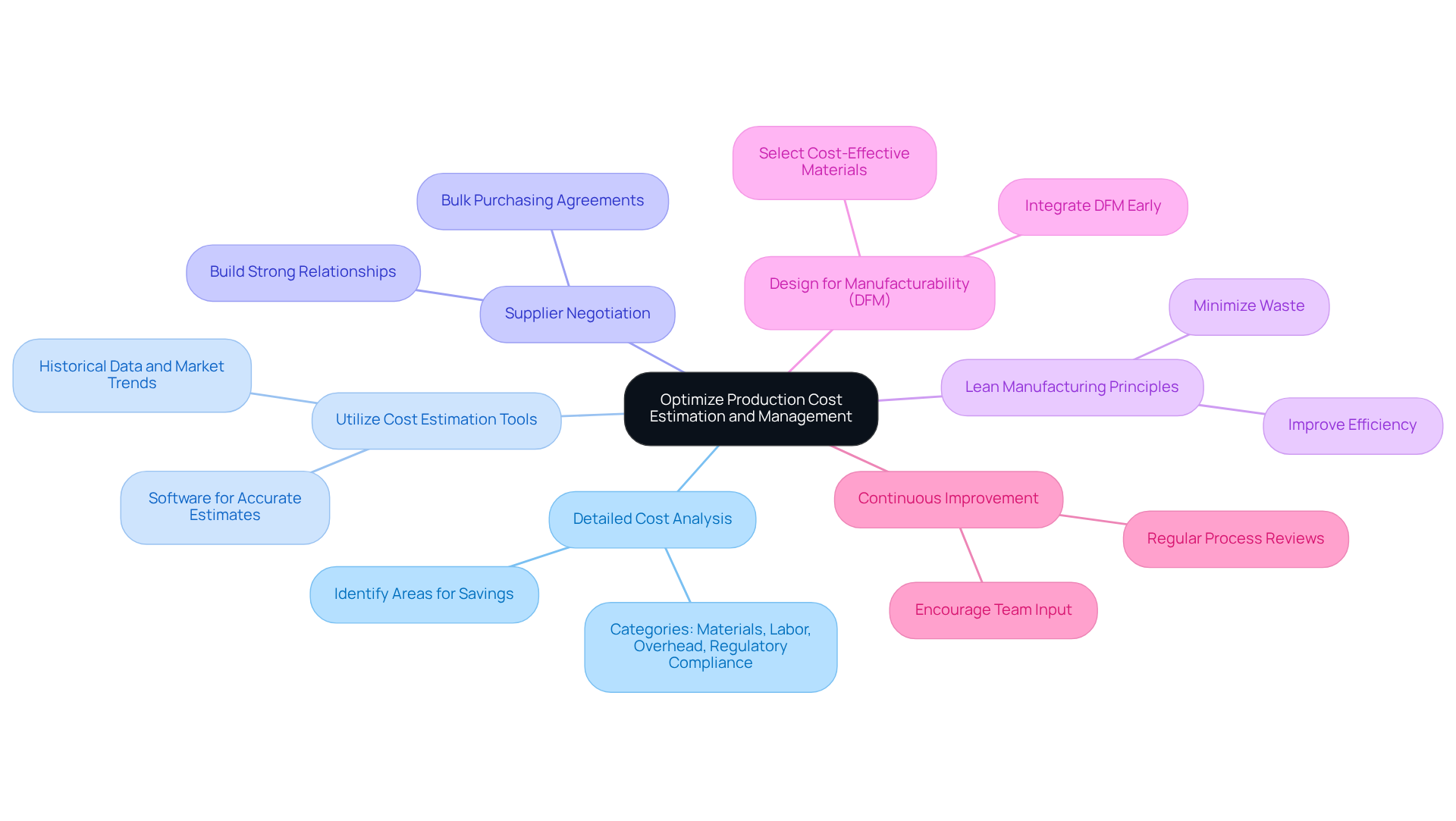

To optimize production cost estimation and management in medical device development, consider the following strategies, integrating principles from successful engineering design projects:

Detailed Cost Analysis: Break down costs into categories such as materials, labor, overhead, and regulatory compliance. This thorough examination aids in pinpointing areas for possible savings, particularly as the healthcare equipment market is anticipated to reach $678.88 billion by 2025, highlighting the necessity for efficient cost management.

Utilize Cost Estimation Tools: Implement software tools that provide accurate cost estimates based on historical data and current market trends. These tools can enhance forecasting accuracy, aligning with the latest trends in cost estimation technologies.

Supplier Negotiation: Build strong relationships with suppliers to negotiate better pricing and terms. Consider bulk purchasing agreements to reduce material costs, which can be crucial in a competitive market.

Lean Manufacturing Principles: Adopt lean manufacturing techniques to minimize waste and improve efficiency. This approach can significantly reduce production costs while maintaining quality, addressing common pitfalls in cost management.

Design for Manufacturability (DFM): Integrate DFM principles early in the development process to simplify manufacturing and lower costs. This includes selecting materials and processes that are cost-effective and easy to produce, ensuring manufacturability from the outset.

Continuous Improvement: Establish a culture of continuous improvement where team members are encouraged to identify cost-saving opportunities and process enhancements. As Trever White noted, small improvements can accumulate to create significant gains. Regularly review production processes to identify inefficiencies.

By applying these strategies, companies such as Voler Systems can efficiently oversee production expenses while guaranteeing high-quality healthcare products through electronic product design and development, utilizing insights from successful engineering projects.

To enhance design efficiency in medical device development, companies should consider the following advanced approaches:

Computer-Aided Design (CAD): Companies should utilize CAD software to produce accurate layouts and simulations. This enables quick prototyping and iteration, significantly decreasing creation time while enhancing precision. Such technology is crucial for contemporary medical equipment development.

3D Printing: Employing 3D printing for rapid prototyping and testing of component parts allows for swift adjustments and reduces material waste. This method facilitates quicker iterations and more efficient development processes.

Artificial Intelligence (AI): Integrating AI-driven tools for data analysis and predictive modeling can detect structural issues early in the development process. AI optimizes performance based on user feedback, thereby enhancing the overall dependability of medical equipment.

Digital Twins: Utilizing digital twin technology generates virtual representations of equipment that can be tested and analyzed in real-time. This approach enhances comprehension of equipment performance and user interaction, paving the way for more intuitive designs.

Collaboration Platforms: Adopting cloud-based collaboration tools facilitates communication and document sharing among team members. These platforms streamline workflows and enhance project management, ensuring that all stakeholders remain aligned throughout the development process.

Automated Testing: Employing automated testing solutions efficiently meets compliance and performance standards. Automation minimizes human errors and accelerates the testing process, guaranteeing that products are safe and effective before entering the market.

By embracing these advanced technologies, medical device companies can significantly enhance their electronic product design and development efficiency, reduce time-to-market, and improve overall product quality, positioning themselves for success in a rapidly evolving industry.

The electronic product design and development process for medical devices represents a complex journey that necessitates meticulous attention at every stage, from initial concept development to market launch. By adhering to established practices and utilizing advanced technologies, companies can enhance product quality while ensuring compliance with essential regulatory standards, ultimately facilitating successful market entry.

Key insights from the article underscore the significance of comprehensive market research, feasibility analysis, and the integration of advanced tools such as CAD and AI during the creation and prototyping phases. Furthermore, maintaining a robust quality management system and conducting thorough testing are crucial for fulfilling user requirements and meeting regulatory demands. The focus on cost management strategies, including detailed cost analysis and lean manufacturing principles, further highlights the imperative for efficiency in production.

As the medical technology landscape continues to evolve, adopting these best practices and advanced methodologies will be vital for companies striving to excel in this competitive arena. By prioritizing user needs, regulatory compliance, and innovative technologies, stakeholders can significantly enhance the safety, efficacy, and overall success of medical devices, ultimately improving patient outcomes and advancing healthcare solutions.

What are the key stages of the electronic product design and development process for medical devices?

The key stages include Concept Development, Feasibility Analysis, Creation and Prototyping, Testing and Validation, Regulatory Submission, Production Planning, and Market Launch.

What is involved in the Concept Development phase?

The Concept Development phase involves identifying the need for a new product, conducting market research, and defining user requirements. Understanding market dynamics is crucial, especially with the projected growth of the medical technology sector in India.

What is assessed during the Feasibility Analysis stage?

The Feasibility Analysis stage assesses technical feasibility, regulatory requirements, and potential market barriers. It also considers evolving FDA evaluation processes, especially for software-driven and AI-enabled devices.

What tools are used in the Creation and Prototyping phase?

Advanced tools like CAD software are used in the Creation and Prototyping phase to ensure precision in developing initial concepts and prototypes, focusing on functionality and user experience.

What types of testing are performed during the Testing and Validation stage?

Rigorous testing, including usability testing and performance evaluations, is conducted to validate designs against user requirements and regulatory standards.

Why is Regulatory Submission important in the development process?

Regulatory Submission is crucial as it involves preparing and submitting documentation for regulatory approval, ensuring compliance with standards like ISO 13485 and FDA regulations to avoid delays in market entry.

What does Production Planning entail?

Production Planning involves developing a comprehensive manufacturing plan, sourcing materials, selecting suppliers, and establishing efficient production workflows, with strategies like reshoring to enhance supply chain resilience.

What is the focus during the Market Launch stage?

The Market Launch stage focuses on executing the launch strategy, including marketing and distribution plans, as well as overseeing post-market performance for continual enhancement and compliance.