Define M2M: A Step-by-Step Guide for Medical Device Manufacturers

Learn how to define M2M technology and its impact on medical device manufacturing.

Understanding the nuances of Electrically Erasable Programmable Read-Only Memory (EEPROM) is essential for advancing medical device design. This non-volatile memory technology is critical in ensuring that vital patient data and device configurations remain intact, even during power interruptions. As healthcare technology continues to evolve, the demand for reliable, high-capacity memory solutions increases. This trend compels engineers to address the complexities associated with traditional EEPROM limitations while exploring innovative alternatives, such as emulated EEPROM.

How can designers effectively leverage these technologies to enhance device reliability and ensure patient safety in the face of growing challenges?

To define EEPROM, one must understand that Electrically Erasable Programmable Read-Only Memory is a vital form of non-volatile memory that retains information even when power is turned off. This feature is particularly important in healthcare devices, where the integrity of patient information and device settings must be reliably maintained. In healthcare electronics, to define EEPROM, it is commonly used to store calibration data, configuration parameters, and other essential details that need to persist through power cycles. Its rewritable nature allows for multiple updates without requiring chip replacement, making it ideal for dynamic environments that necessitate frequent updates.

Recent advancements in non-volatile memory technology have significantly enhanced performance and reliability in healthcare applications. For instance, the integration of advanced error correction algorithms and wear-leveling techniques has improved data integrity, ensuring that the memory can withstand millions of write/erase cycles. This is especially critical as the healthcare sector increasingly demands high-capacity, durable memory chips to support sophisticated devices, driven by the miniaturization of healthcare instruments and the expansion of telehealth solutions.

Statistics indicate that the memory chips market is projected to grow at a compound annual growth rate (CAGR) of approximately 7.5%, underscoring the rising reliance on these components in healthcare technology. Practical examples of EEPROM in healthcare electronic design include its use in portable devices such as insulin pumps, heart monitors, and hearing aids, where it securely stores vital configurations and patient information between uses. This capability not only enhances patient safety but also ensures that critical information is readily accessible when required.

Industry leaders who define EEPROM emphasize its reliability in healthcare electronics, highlighting its importance in maintaining data integrity across various applications. As the demand for secure, efficient, and dependable healthcare instruments continues to increase, this technology remains a cornerstone, enabling manufacturers to comply with stringent regulatory standards while improving patient outcomes.

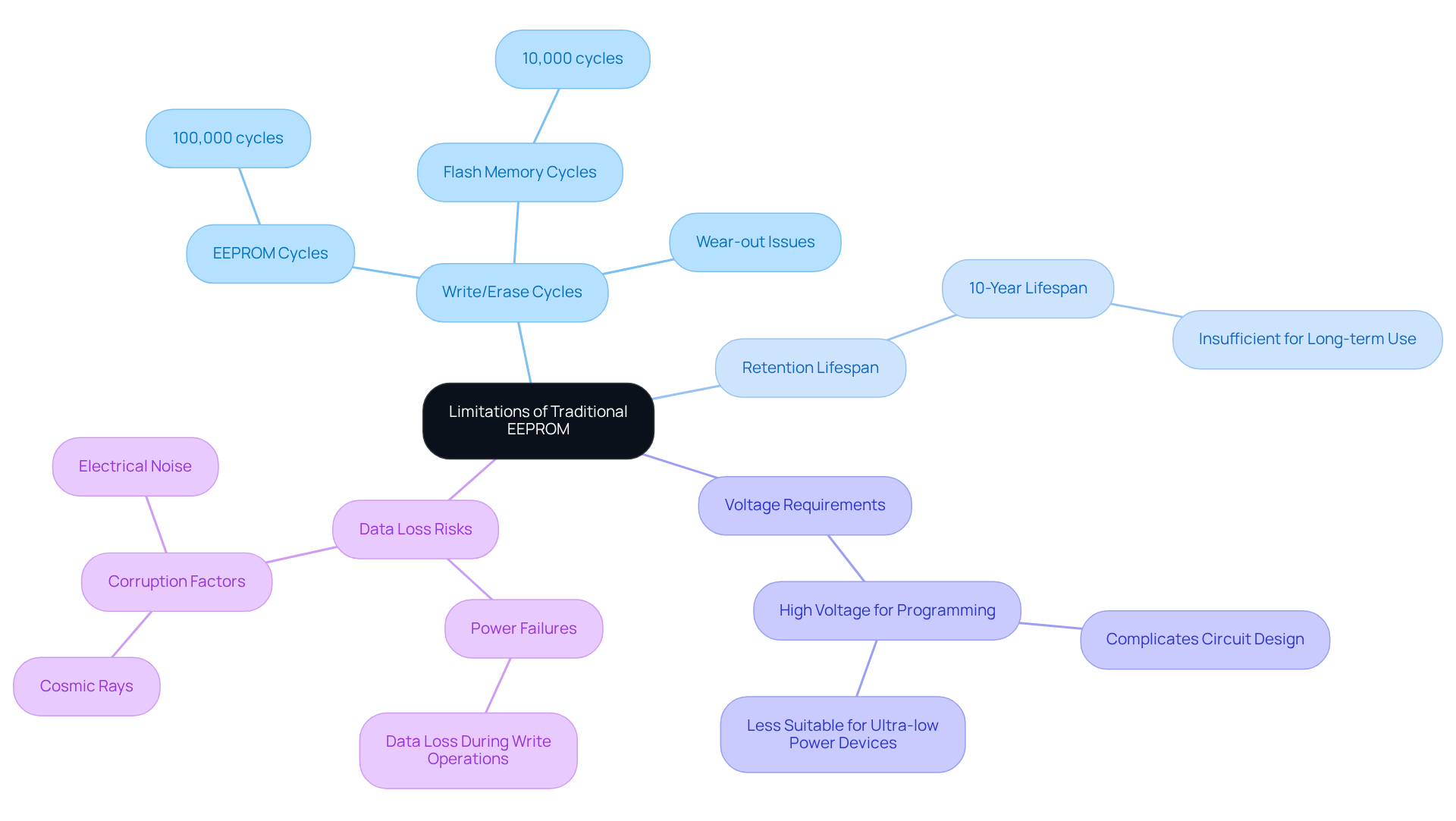

Conventional memory technology presents several limitations that significantly affect its application in healthcare tools. To define EEPROM, a primary concern is the limited number of write/erase cycles, which typically ranges from 100,000 cycles for EEPROM to approximately 10,000 for Flash Memory. This limitation can lead to wear-out issues in devices that require frequent updates, particularly in dynamic healthcare environments where information is regularly modified. Furthermore, when we define EEPROM, it is important to note that conventional EEPROMs generally have a retention lifespan of about 10 years, which may prove insufficient for long-term healthcare applications where reliability is paramount.

The high voltage required for programming and erasing electrically erasable programmable read-only memory complicates circuit design, rendering it less suitable for ultra-low power devices that are increasingly prevalent in the healthcare sector. Additionally, challenges such as data loss during power failures, especially during write operations, further hinder efforts to define EEPROM in critical applications. Understanding these limitations is essential for engineers to make informed decisions regarding memory solutions, ensuring that the products they develop meet the stringent reliability and performance standards necessary in the healthcare industry.

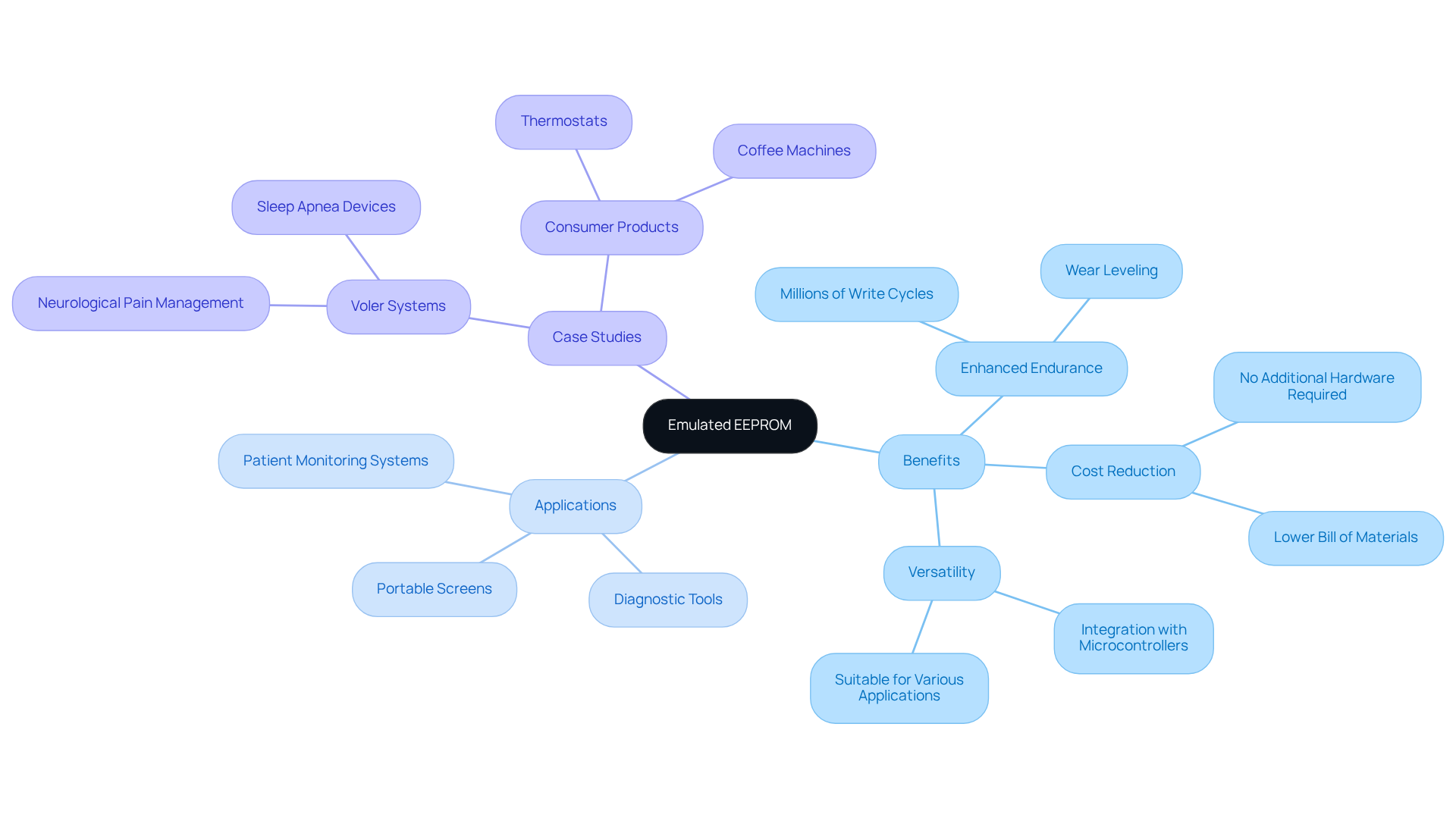

Emulated flash memory utilizes flash storage to replicate the features of traditional programmable read-only memory, providing numerous advantages for modern healthcare equipment. A primary benefit is its significantly enhanced endurance, allowing for millions of write cycles, which greatly exceeds the limited cycles of conventional non-volatile memory. This characteristic makes emulated non-volatile memory particularly suitable for applications requiring frequent updates, such as storing user preferences or calibration data in healthcare devices.

Moreover, to define EEPROM, electrically erasable programmable read-only memory can be integrated seamlessly with existing flash memory, reducing the need for additional components. This integration not only lowers costs but also conserves board space. Its versatility allows for easy incorporation into various microcontroller architectures, solidifying its status as a preferred solution in contemporary healthcare equipment design.

Practical applications illustrate its effectiveness, with devices like portable screens and diagnostic tools employing emulated memory for reliable storage and retrieval. Voler Systems is at the forefront of these advancements, implementing emulated memory in their cutting-edge medical instruments, including those designed for neurological pain management and sleep apnea. By integrating Edge AI, Voler Systems enhances the capabilities of simulated memory, facilitating more intelligent data management and improved patient outcomes. Case studies highlight the application of these technologies in pain therapy innovation, underscoring Voler Systems' commitment to advancing healthcare technology.

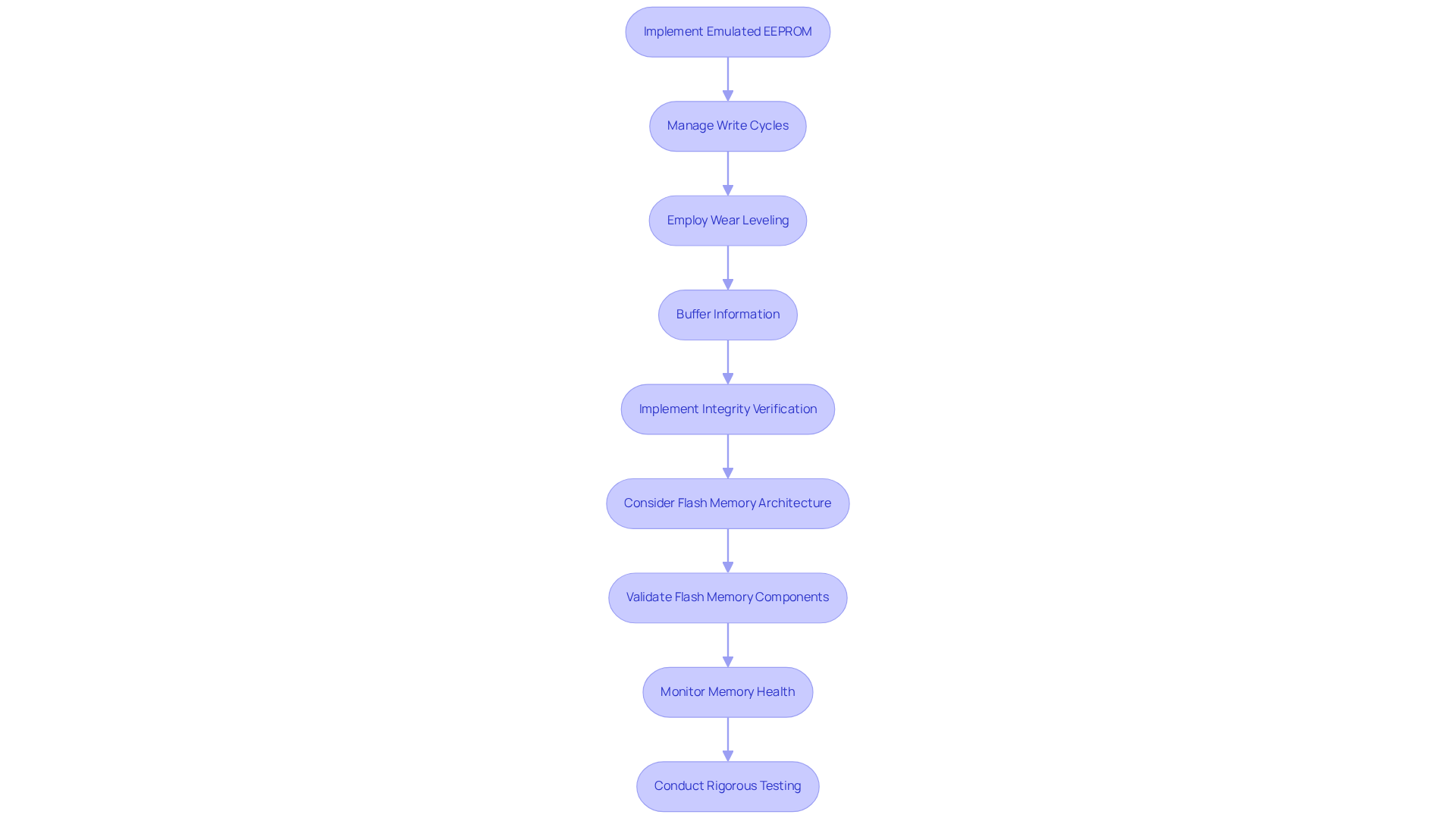

To enhance the performance and reliability of simulated memory in medical devices, several design strategies must be implemented. Effective management of write cycles is crucial; employing wear leveling techniques ensures that write and erase cycles are evenly distributed across the memory, significantly prolonging its lifespan. For example, to define EEPROM, it is important to note that emulated EEPROM can support up to 100 million write cycles, which represents a considerable improvement compared to traditional EEPROM, which typically endures only 100,000 to 1 million cycles.

Furthermore, buffering information before writing can further reduce the frequency of writes, thereby minimizing wear on the memory. Implementing checksums or CRCs for integrity verification is also essential, as it helps maintain the accuracy and reliability of stored information, protecting against corruption.

Moreover, careful consideration of the flash memory architecture and the specific microcontroller in use is vital for optimizing the emulation process. This ensures compatibility and enhances overall performance, particularly in environments where information integrity is critical, such as healthcare applications. Additionally, validating flash memory components for medical applications is imperative to confirm their suitability and reliability. Manufacturers must also recognize the risks associated with power loss during write operations, as this can result in corruption or loss of information. By adhering to these best practices and employing rigorous testing strategies, manufacturers can significantly improve the reliability and lifespan of emulated memory in their devices.

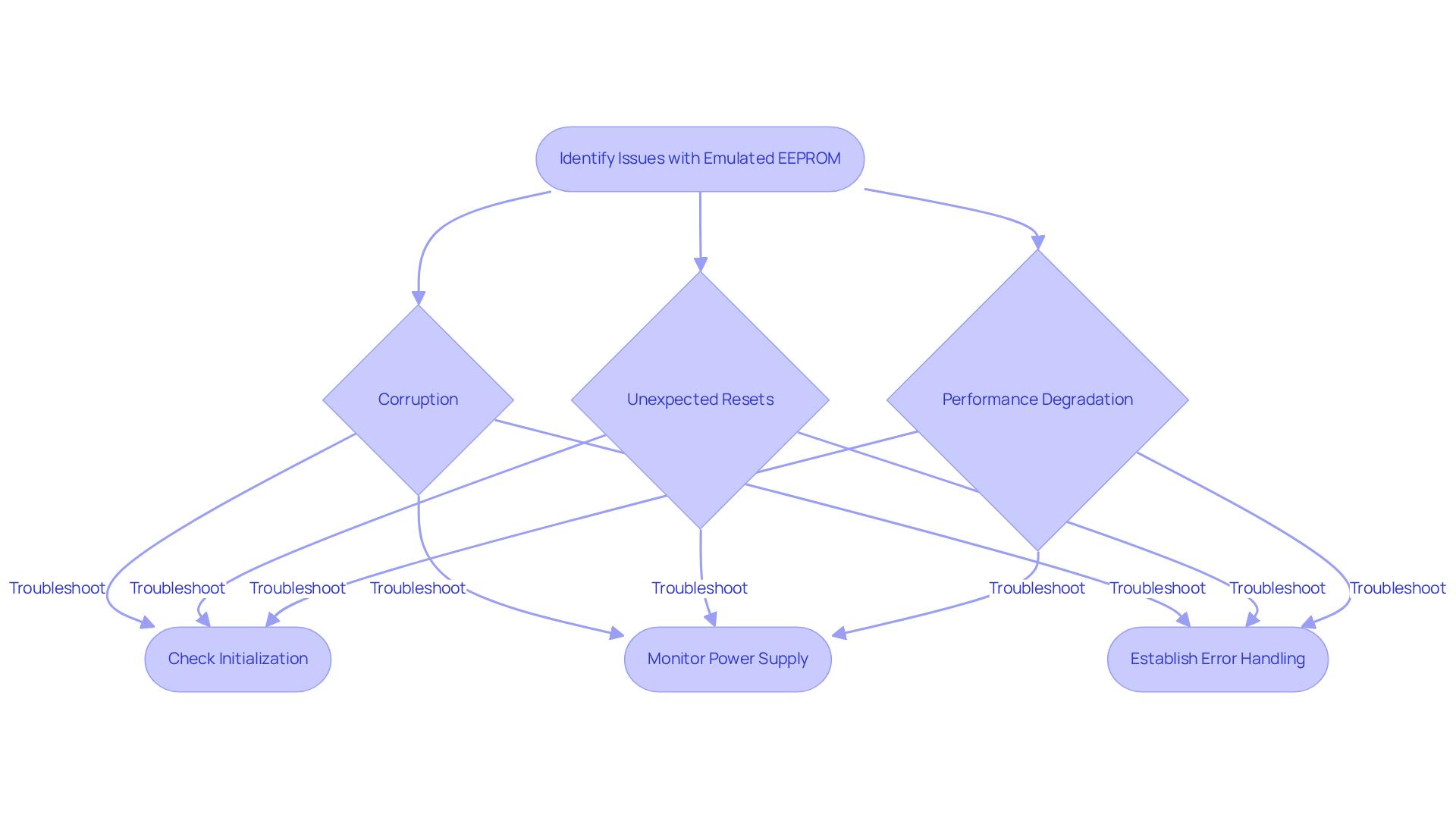

Common issues encountered with emulated electrically erasable programmable read-only memory (EEPROM) include corruption, unexpected resets, and performance degradation. To troubleshoot these problems, it is essential to first ensure that the memory is correctly initialized and that the write and erase operations are performed as intended. As Vsevolod Lapshin observes, "EEPROM error occurs when its contents do not match the information that was transmitted to it," which underscores the importance of precise information management.

Establishing a robust error handling system can aid in recognizing when corruption occurs, allowing for timely corrective measures. Additionally, monitoring the power supply during writing processes is crucial, as fluctuations can lead to incomplete writes and data loss. The typical retention duration for data on a non-volatile memory component is 10 to 15 years, highlighting the necessity for reliability in healthcare applications.

Consistently testing the emulated memory chip under various conditions can also help identify potential design flaws, enabling proactive modifications before deployment. By addressing these common issues with targeted solutions, developers can significantly enhance the reliability and performance of emulated EEPROM, which is important to define EEPROM in medical devices.

Electrically Erasable Programmable Read-Only Memory (EEPROM) is essential in the design of medical devices, ensuring that critical data remains intact even in the absence of power. Its capability to preserve patient information and device settings is vital in healthcare applications, where reliability and data integrity are of utmost importance. As the demand for advanced medical technology escalates, comprehending the significance of EEPROM becomes increasingly crucial for designers and manufacturers.

This article explores the various aspects of EEPROM, including its traditional limitations, such as the finite number of write cycles and challenges in ultra-low power applications. It also emphasizes the rise of emulated EEPROM as a superior alternative, providing enhanced endurance and seamless integration with existing systems. Key design strategies and best practices are presented to optimize the performance of emulated memory, ensuring that healthcare devices can adhere to stringent standards for reliability and efficiency.

Ultimately, advancements in EEPROM technology highlight its significance in the evolving landscape of medical devices. As healthcare continues to adopt innovative solutions, prioritizing the implementation of reliable memory systems will be essential for enhancing patient safety and improving outcomes. Adopting these technologies not only ensures compliance with regulatory standards but also lays the groundwork for the future of healthcare innovation.

What is EEPROM and why is it important in electronics design?

EEPROM stands for Electrically Erasable Programmable Read-Only Memory, which is a type of non-volatile memory that retains information even when power is off. Its importance in electronics design, particularly in healthcare devices, lies in its ability to reliably maintain patient information and device settings, store calibration data, and configuration parameters that need to persist through power cycles.

How does EEPROM enhance performance in healthcare applications?

Recent advancements in EEPROM technology, such as the integration of error correction algorithms and wear-leveling techniques, have improved performance and reliability. These enhancements ensure data integrity and allow the memory to withstand millions of write/erase cycles, which is crucial for sophisticated healthcare devices and telehealth solutions.

What are some practical applications of EEPROM in healthcare electronics?

EEPROM is commonly used in portable healthcare devices like insulin pumps, heart monitors, and hearing aids. It securely stores vital configurations and patient information, enhancing patient safety and ensuring critical information is readily accessible when needed.

What are the limitations of traditional EEPROM?

Traditional EEPROM has several limitations, including a limited number of write/erase cycles (approximately 100,000 cycles) and a retention lifespan of about 10 years. These factors can lead to wear-out issues in devices requiring frequent updates and may be insufficient for long-term healthcare applications.

Why is the high voltage requirement for EEPROM a concern in healthcare devices?

The high voltage required for programming and erasing EEPROM complicates circuit design, making it less suitable for ultra-low power devices that are increasingly common in the healthcare sector.

What challenges are associated with using EEPROM in critical applications?

Challenges include the potential for data loss during power failures, especially during write operations, and the limitations in write/erase cycles. These issues must be understood by engineers to ensure that memory solutions meet the reliability and performance standards necessary in healthcare.