10 Essential Parts of a Product for Medical Device Manufacturers

Explore the key parts of a product essential for medical device manufacturers to enhance...

The complex realm of medical device design integrates innovation, precision, and regulatory compliance, with each component playing a critical role in enhancing patient care. As healthcare technology advances rapidly, it is essential for manufacturers to grasp the fundamental aspects of product design to deliver effective and safe medical solutions. This raises pertinent questions:

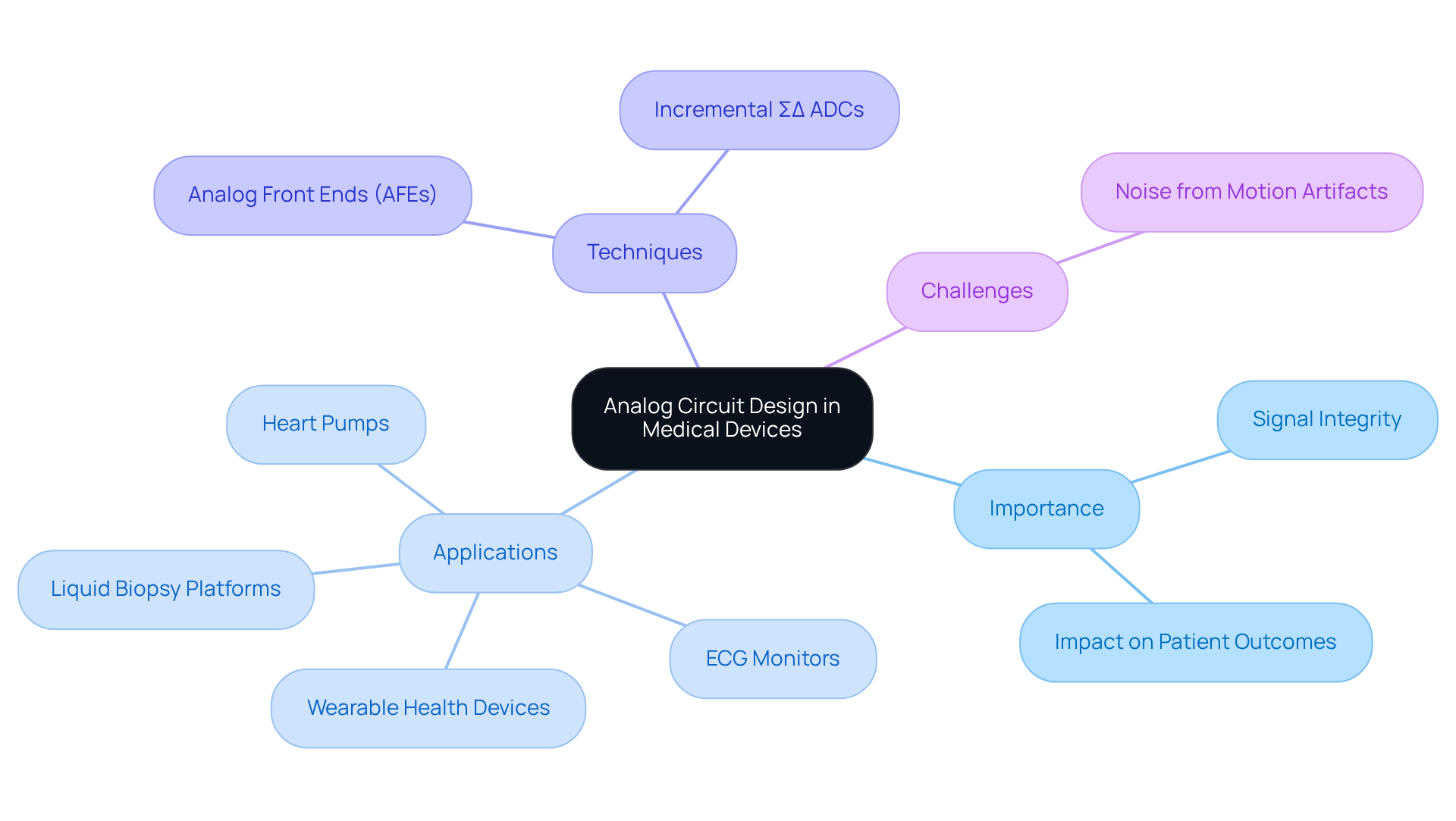

Analog circuit design plays a crucial role in the functionality of healthcare instruments, facilitating precise signal processing and data collection. The company specializes in this domain, ensuring that instruments accurately capture and interpret physiological signals, which is vital for applications such as ECG monitors, wearable health devices, heart pumps, and liquid biopsy platforms. The integrity of these signals, which are critical elements of product efficacy, directly impacts patient outcomes; even minor inaccuracies can result in significant misdiagnoses. By utilizing advanced analog design techniques, including the integration of analog front ends (AFEs), Voler Systems enhances the reliability of medical devices by focusing on the elements of product, thereby contributing to improved patient care.

Our expert electronic design services, bolstered by AI-assisted engineering, focus on the elements of product creation to enable the development of high-quality healthcare products that are both innovative and efficient. For example, successful projects in ECG monitor design have shown that the elements of product, including robust analog circuits, can effectively reduce noise and optimize signal clarity, ensuring accurate readings. Incremental ΣΔ ADCs, capable of achieving over 15 bits of effective number of bits (ENOB) under optimal conditions, exemplify the performance potential of high-quality analog designs.

Moreover, addressing challenges such as noise from motion artifacts in wearable ECG applications is essential for preserving signal integrity. As the medical technology landscape continues to evolve, the significance of high-quality analog design remains critical, underscoring the elements of product that are essential for delivering effective healthcare solutions and facilitating the transition from tethered systems to truly wireless solutions.

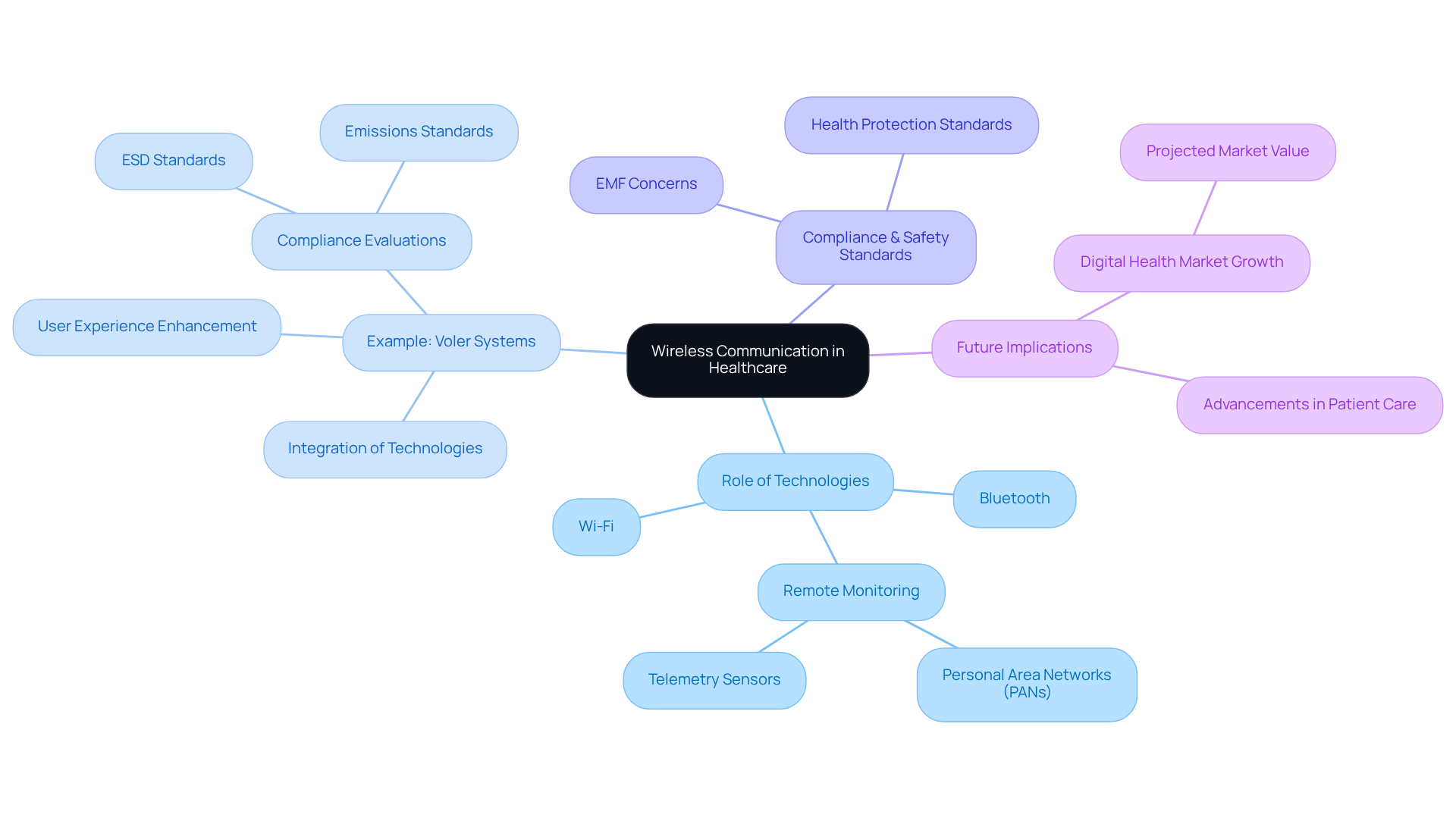

Wireless communication technologies, such as Bluetooth and Wi-Fi, play a crucial role in the functionality of modern medical equipment. They facilitate seamless data transfer between devices and healthcare providers, enabling remote monitoring and timely interventions that significantly enhance patient care. For example, the use of personal area networks (PANs) created by telemetry sensors allows for continuous patient monitoring, irrespective of location, thereby improving care delivery across various settings.

Voler Systems stands out in integrating these technologies into their designs, ensuring effective communication among devices in diverse environments. This capability not only streamlines workflows but also enhances the user experience by reducing dependence on physical connections. Furthermore, the organization conducts thorough compliance evaluations to ensure that all equipment meets emissions and ESD standards, reinforcing its commitment to safety and innovation.

As the healthcare sector increasingly embraces wireless solutions, prioritizing safety and adherence to health protection standards becomes essential, especially given the rising levels of electromagnetic fields (EMF). The ongoing advancement of wireless communication is poised to redefine patient care, making it more efficient and accessible in 2026 and beyond.

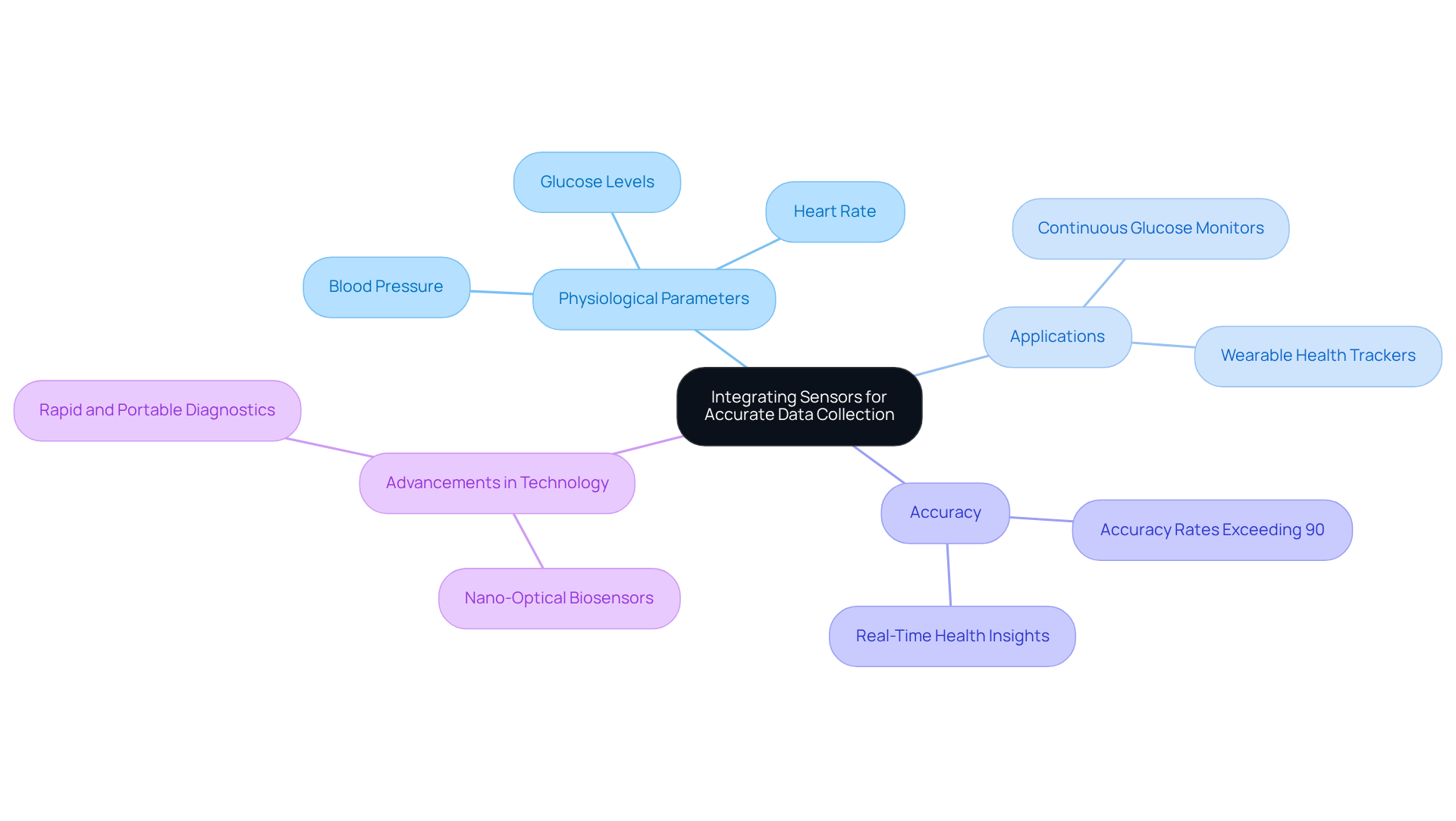

Integrating sensors into medical devices is essential for precise data collection and monitoring. These sensors accurately measure a variety of physiological parameters, including heart rate, blood pressure, and glucose levels. Voler Systems specializes in selecting and integrating the most suitable sensors for each application, ensuring high accuracy and reliability. This expertise is particularly critical for devices such as continuous glucose monitors, which have demonstrated accuracy rates exceeding 90%, and wearable health trackers that provide real-time health insights. The ability to collect accurate data is vital for effective patient management, enabling timely interventions and personalized treatment plans. Furthermore, advancements in sensor technology, such as nano-optical biosensors, facilitate rapid and portable diagnostics, thereby enhancing the depth of health data available to clinicians. By leveraging these innovations, Voler Systems ensures that healthcare instruments not only meet stringent industry requirements but also promote proactive health management.

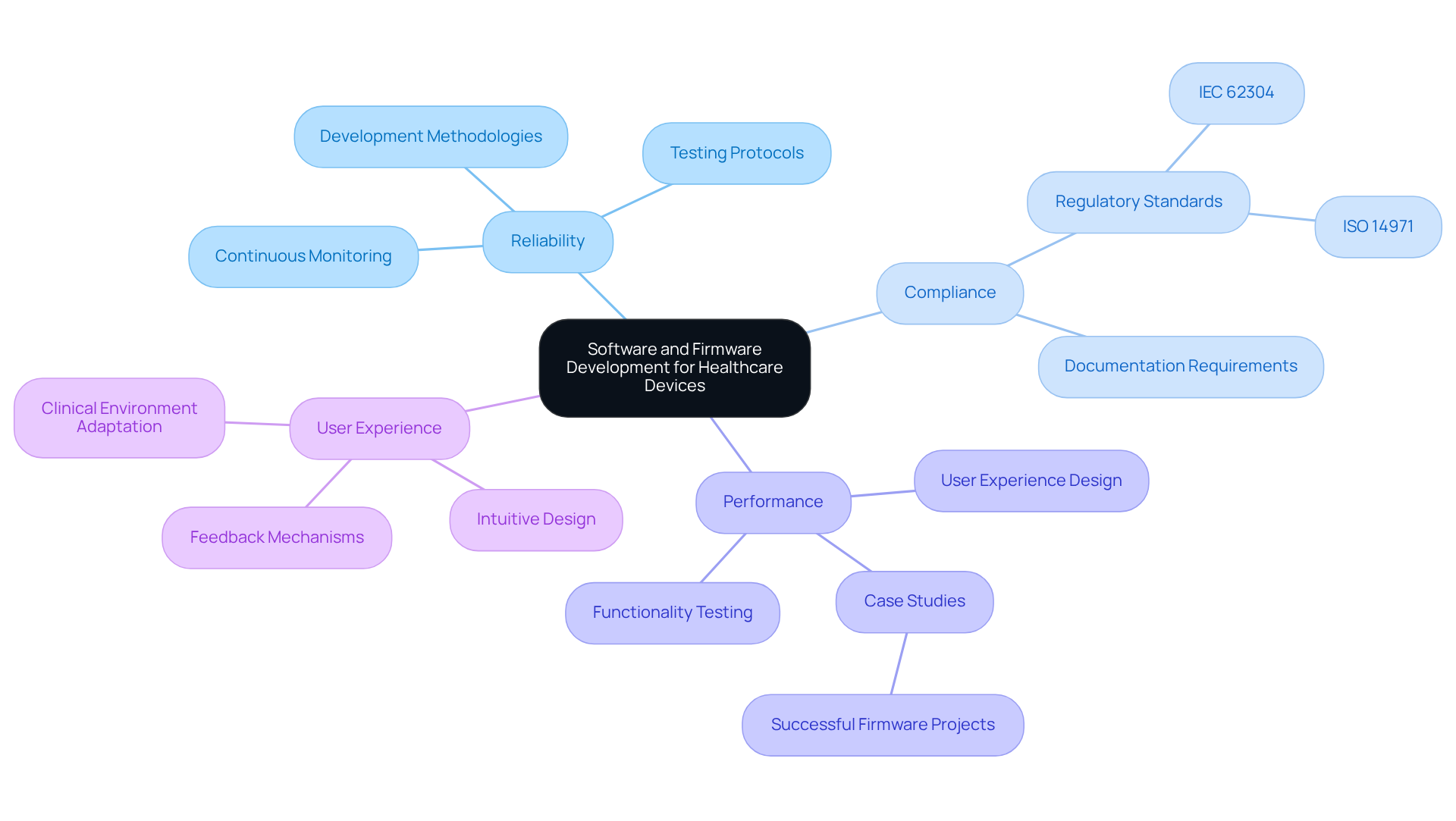

The dependability of healthcare instruments is fundamentally linked to the development of software and firmware, which control functionalities, manage data, and ensure compliance with stringent regulatory standards. By 2026, the significance of robust firmware is highlighted by the growing complexity of medical devices and the imperative for enhanced safety measures.

Voler Systems employs rigorous development methodologies that prioritize software reliability, ensuring that devices not only fulfill compliance requirements but also excel in performance and user experience. This emphasis on intuitive design and functionality is crucial for seamless operation in clinical environments, ultimately contributing to improved patient care outcomes.

Successful firmware development projects within the healthcare equipment sector illustrate the critical connection between software reliability and the elements of product performance, underscoring the necessity for manufacturers to invest in high-quality firmware solutions.

Motion control systems are vital for medical devices that require precise movements, especially in robotic surgical instruments and infusion pumps. The company employs cutting-edge motion control technologies, integrating advancements in artificial intelligence to guarantee that equipment operates with exceptional precision and reliability. This level of precision is critical in situations where even minor deviations can result in significant consequences. By emphasizing motion control, the company markedly improves the elements of product functionality and safety in its healthcare equipment, leading to better patient outcomes.

The incorporation of advanced motion control not only addresses the complex requirements of surgical procedures but also aligns with the increasing trend of robotic-assisted surgeries, which have risen to over 14 million annually. As surgical robotics continue to advance, the significance of precision in motion control becomes more apparent, directly impacting patient safety and the overall success of surgical interventions. Furthermore, the company's innovative development of precision positioning solutions highlights its commitment to enhancing healthcare technology, particularly in areas related to neurological pain management and sleep apnea.

Field Programmable Gate Arrays (FPGAs) offer a distinct advantage in the design of medical devices by enabling customizable hardware solutions. Voler Systems utilizes FPGA technology to create devices specifically tailored for applications such as wearable devices and heart pumps, thereby enhancing the elements of product performance and functionality. This adaptability is essential in dynamic fields like medical imaging and diagnostics, where requirements often change.

For instance, FPGA implementations in healthcare imaging have demonstrated real-time processing capabilities, significantly reducing image reconstruction times and improving diagnostic accuracy. By leveraging FPGAs alongside AI-assisted engineering, Voler Systems ensures that the elements of product for their medical devices not only meet current technological demands but also remain adaptable for future advancements, facilitating rapid updates and enhancements as new needs emerge.

This strategic approach positions their products at the forefront of healthcare technology, ultimately contributing to improved patient outcomes and operational efficiency. In a market characterized by a high demand for innovative healthcare solutions, Voler Systems is well-equipped to provide expert electronic design services.

Embedded systems play a crucial role in the design of compact and efficient medical devices, integrating hardware and software to perform specific functions such as monitoring and data processing. At Voler Systems, the emphasis is on developing embedded solutions that optimize size and improve power consumption without sacrificing performance. These systems are characterized by advanced processing capabilities, low power consumption, and robust data handling, which are essential for wearable health monitors and portable diagnostic tools.

The integration of these sophisticated embedded systems leads to more intelligent solutions that can deliver real-time data, thereby enhancing patient outcomes and fostering proactive healthcare management. Successful designs in this field illustrate how compactness and efficiency can coexist, ultimately driving innovation in healthcare technology.

Ultra-low power solutions are essential for the development of battery-operated medical equipment, enabling prolonged operation without the need for frequent recharging. Voler Systems specializes in crafting energy-efficient designs that maximize battery life while maintaining high performance, particularly through AI-enabled electronic design. This focus is critical for wearable health monitors and implantable systems, where user convenience and reliability are of utmost importance.

Environmental factors such as moisture and temperature can significantly impact the effectiveness and durability of wearable sensors. By prioritizing low-energy design and addressing these environmental challenges, Voler Systems not only extends battery lifespan but also fosters greater satisfaction and trust in these vital health technologies. This approach incorporates elements of product that pave the way for innovative wearable health products that continuously monitor vital signs.

AI-driven engineering is fundamentally transforming the landscape of healthcare equipment design, facilitating the creation of smarter and more efficient solutions. The company employs advanced AI technologies, such as predictive analytics and generative design tools, to optimize design processes, enhance functionality, and accurately predict performance outcomes. This innovative approach accelerates the development of healthcare instruments that are not only state-of-the-art but also adaptable to the evolving demands of the industry.

By integrating AI into their workflows, Voler Systems is well-positioned to deliver products that significantly enhance patient outcomes, aligning with the industry's transition towards adaptive and intelligent healthcare solutions. With nearly half of medical device manufacturers planning to incorporate AI into their development processes within the next two years, the potential for AI to streamline time-to-market and minimize friction points in design is becoming increasingly apparent. Moreover, the application of GenAI tools is anticipated to reduce engineering time by 20-30%, highlighting the efficiency advantages of AI.

This evolution underscores the importance of designing for regulatory compliance from the outset, which ensures faster approvals and mitigates development risks. The compliance review process within the organization, which includes comprehensive assessments to meet emissions and ESD standards, is essential in addressing the rigorous demands of modern healthcare environments. Testimonials from satisfied customers further affirm the commitment to excellence in healthcare product design and compliance.

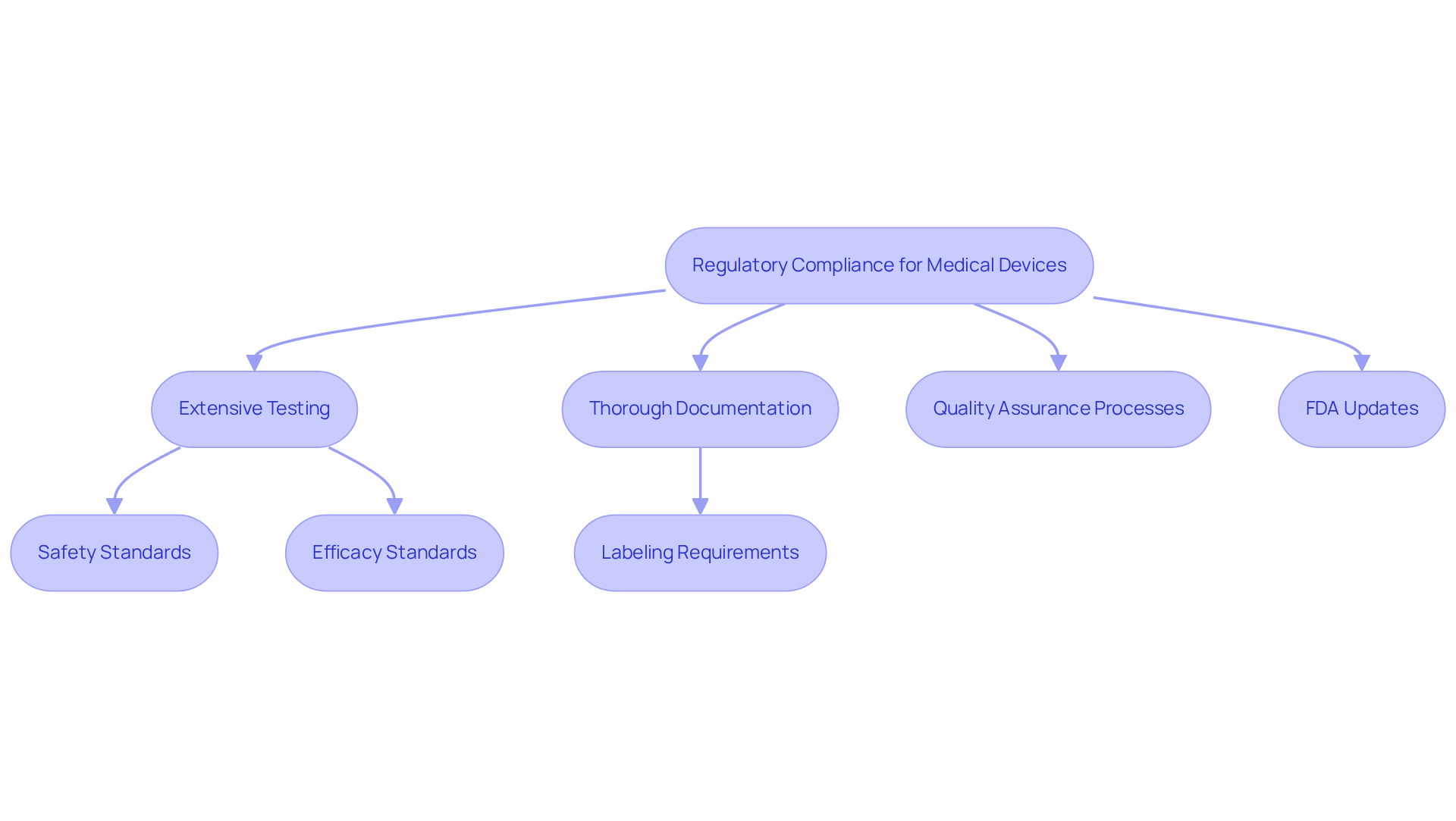

Regulatory compliance plays a vital role in the design of healthcare instruments, ensuring adherence to the safety and efficacy standards mandated by the FDA and other regulatory authorities. Voler Systems is committed to maintaining rigorous compliance through extensive testing, thorough documentation, and robust quality assurance processes. This dedication not only protects patient health but also enhances the credibility and marketability of medical devices, particularly in the context of evolving drug price transparency reporting.

Recent updates from the FDA, dated January 6, 2026, provide clarifications regarding general wellness devices - exempt from standard medical device requirements - and outline the criteria for medical device classification. These updates highlight the necessity of precise labeling and claims in determining regulatory obligations. By prioritizing compliance, Voler Systems effectively positions its products in a competitive market, ensuring they meet the stringent expectations of both regulators and consumers.

The design of medical devices relies on several essential elements that collectively enhance functionality, safety, and patient outcomes. By concentrating on aspects such as:

manufacturers can develop innovative healthcare solutions that address the evolving needs of the industry. Each element is crucial in ensuring that medical devices not only perform effectively but also comply with stringent safety standards.

Key insights from this discussion underscore the significance of:

Moreover, advancements in motion control systems, FPGA development, and ultra-low power solutions illustrate how cutting-edge technologies are being leveraged to expand the capabilities of medical devices. The emphasis on regulatory compliance further highlights the commitment to patient safety and the credibility of healthcare products in a competitive market.

As the landscape of medical technology continues to evolve, embracing these essential elements will be vital for fostering innovation and enhancing patient care. Stakeholders in the healthcare sector are encouraged to prioritize these factors in their product design processes, ensuring that they not only meet current demands but also adapt to future challenges. By doing so, they can contribute to a more effective and responsive healthcare system, ultimately improving the quality of life for patients worldwide.

What is the role of analog circuit design in medical devices?

Analog circuit design is crucial for the functionality of healthcare instruments, enabling precise signal processing and data collection, which is essential for accurately capturing and interpreting physiological signals.

How does Voler Systems enhance the reliability of medical devices?

Voler Systems utilizes advanced analog design techniques, including the integration of analog front ends (AFEs), to improve the reliability of medical devices, which contributes to better patient care.

What are some applications of Voler Systems' analog circuit design?

Applications include ECG monitors, wearable health devices, heart pumps, and liquid biopsy platforms, all of which rely on accurate signal capture for effective performance.

Why is signal integrity important in medical devices?

Signal integrity is vital because even minor inaccuracies in physiological signal capture can lead to significant misdiagnoses, impacting patient outcomes.

How does Voler Systems address challenges in wearable ECG applications?

The company focuses on minimizing noise from motion artifacts to preserve signal integrity, which is essential for accurate monitoring in wearable ECG devices.

What role do wireless communication technologies play in medical devices?

Wireless communication technologies, such as Bluetooth and Wi-Fi, enable seamless data transfer between devices and healthcare providers, facilitating remote monitoring and timely interventions.

How does Voler Systems integrate wireless communication into their designs?

Voler Systems ensures effective communication among devices in various environments, streamlining workflows and enhancing user experience by reducing reliance on physical connections.

What are personal area networks (PANs) and their significance in healthcare?

Personal area networks created by telemetry sensors allow for continuous patient monitoring regardless of location, which improves care delivery across different settings.

What is the importance of sensor integration in medical devices?

Integrating sensors is essential for accurate data collection and monitoring of physiological parameters such as heart rate, blood pressure, and glucose levels, which are crucial for effective patient management.

What advancements in sensor technology does Voler Systems leverage?

Voler Systems utilizes innovations like nano-optical biosensors to facilitate rapid and portable diagnostics, enhancing the depth of health data available to clinicians.