Company: Confidential Leading Research Center

Industry: Technological Research and Development

Use Case: High-Precision Positioning and Optical System

Services Used: Electronic System Design, Signal Routing, Optical Integration, Collaboration with Mechanical Engineering

Results:

- Achieved high-precision control for delicate component handling

- Improved research accuracy with real-time optical monitoring

- Delivered a fully functional system and documentation

Customer Introduction

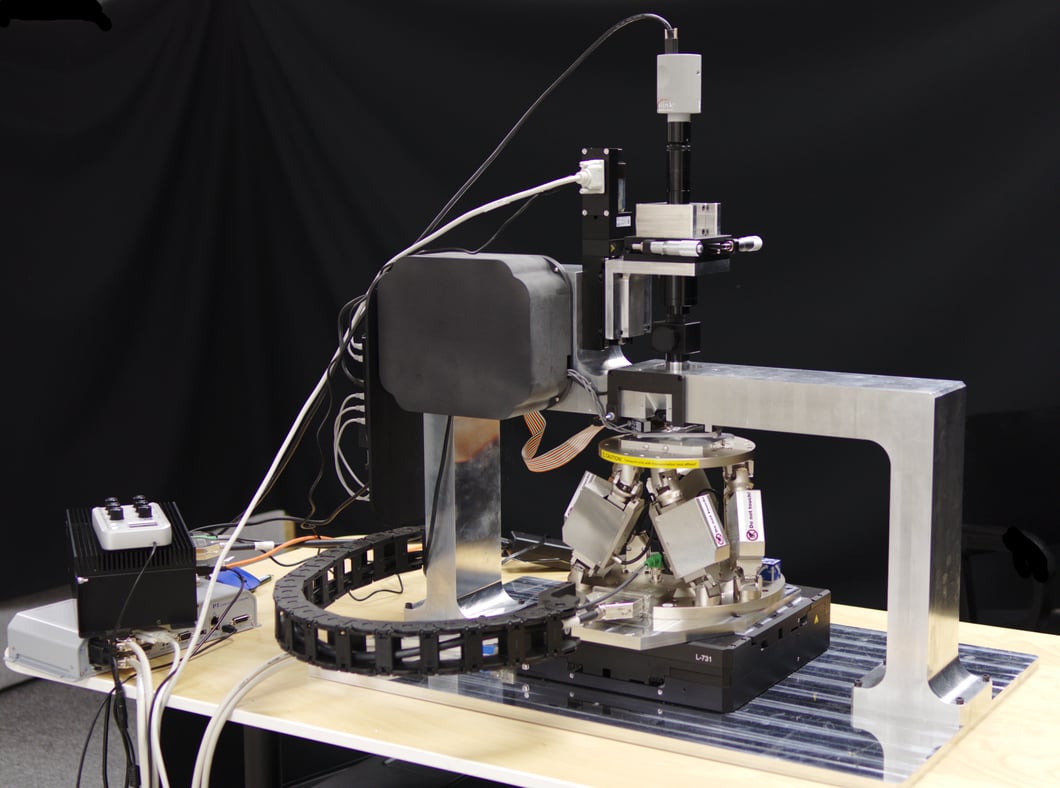

This confidential leading research center in Silicon Valley is a renowned institution that provides advanced research, business collaboration, breakthrough technology IP, and innovation services. It was developing an R&D positioning system for manipulating microscopic components. Voler Systems and Function Engineering, a mechanical engineering firm, collaborated to design a working positioning system that met the research center's specifications.

Problem/Goal

- The system must handle the delicate task of moving microscopic parts from one semiconductor substrate to another without causing damage.

Develop a system that allows exact control over movements across multiple axes and angular adjustments while avoiding any damage during transfer.

- Substrates must remain perfectly aligned during component transfer.

Integrate optical monitoring that enables real-time viewing and adjustment of the positioning process.

- Integration of mechanical, electrical, and optical components.

Facilitate collaborative engineering, resulting in a cohesive and highly precise positioning system.

Solution

Voler Systems was selected for its high-precision electrical system design and optical integration expertise. The project involved several key elements:

- Designing the electrical system that coordinated the movement of the substrates under the fixed head, ensuring precise alignment. This included routing signals to various components and integrating force sensors to monitor and control the delicate process of component transfer.

- Integrating the optical components ensured that the microscope and camera provided the necessary precision and clarity for the researchers to monitor the positioning process. The optics were carefully integrated to work seamlessly with the mechanical positioning system.

- Working in tandem with the mechanical engineering firm responsible for machining the physical parts of the system. This collaboration ensured that the electrical and mechanical components were perfectly aligned and functioned together as intended.

Results & Benefits

- Enhanced precision and control enabled the research center to conduct its work with a high degree of accuracy, significantly improving its ability to manipulate microscopic parts without causing damage.

- Enhanced research capabilities with the integration of real-time monitoring allowed for immediate adjustments, reducing errors and improving the overall quality of the research.

- Successfully delivered a ready-to-use system that met all the technical and performance requirements, meeting the high standards required for a sensitive application.

Inspiration

Voler Systems thrives on transforming complex engineering challenges into innovative solutions. This project highlights our ability to collaborate effectively with our clients and other engineering firms, ensuring that even the most demanding technical requirements are met with precision and expertise.

"Voler Systems delivered exactly what we needed—high-precision engineering and seamless integration. Their expertise was crucial to the success of our project."

Contact Voler Systems today to learn how our tailored engineering solutions can elevate your product innovation and research capabilities.